Product Description

Adjustable roll forming C Section Floor Beam rollformer

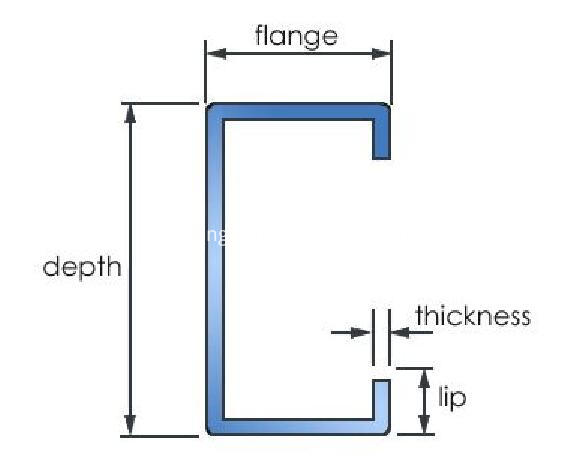

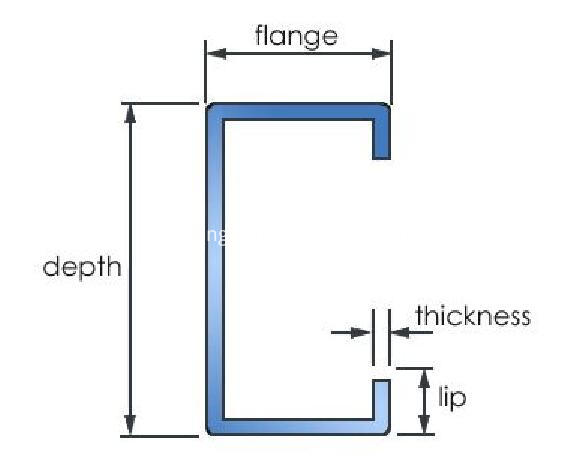

Adjustable roll forming C Section Floor Beam rollformer is a line which can produce different sizes of C purlines by changing the spacer. The character of this adjustable roll forming C Section Floor Beam rollformer is with low cost, and easy to change the space to adjust the size. The thickness of this C section floor beam is 1.5-3.0mm, size is from 80-300mm. For any sizes you need, we will know it and custom design the machine for you. We need to know the flange, the depth, the thickness,the lips.

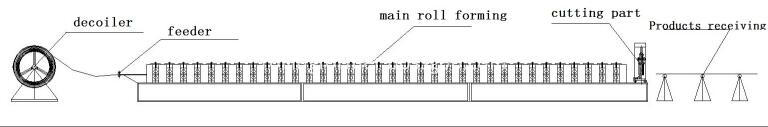

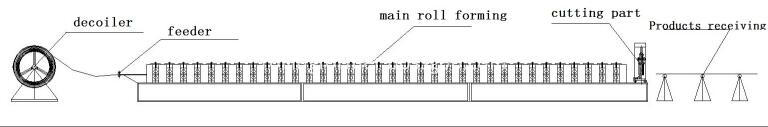

Adjustable roll forming C Section Floor Beam rollformer line is a simple rollformer line including below parts:

The 3 tons manual decoiler, the feeding leveling system, the main roll forming machine, the hydraulic cutting system and receiving table.

Below is the working flow for your reference:

Below are some pictures for your reference:

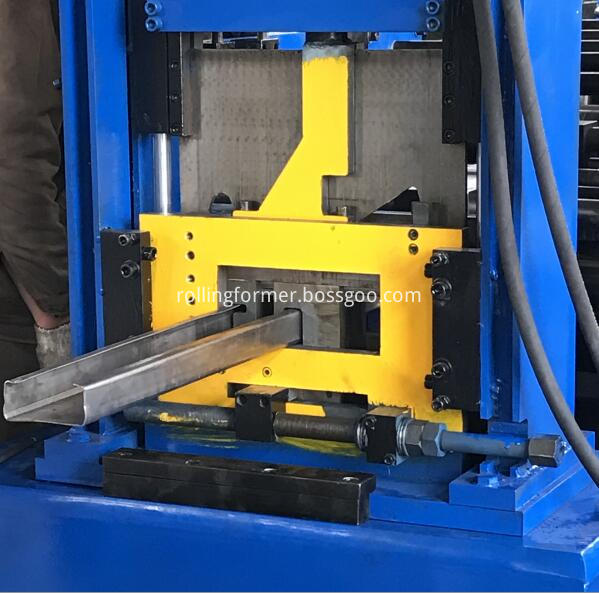

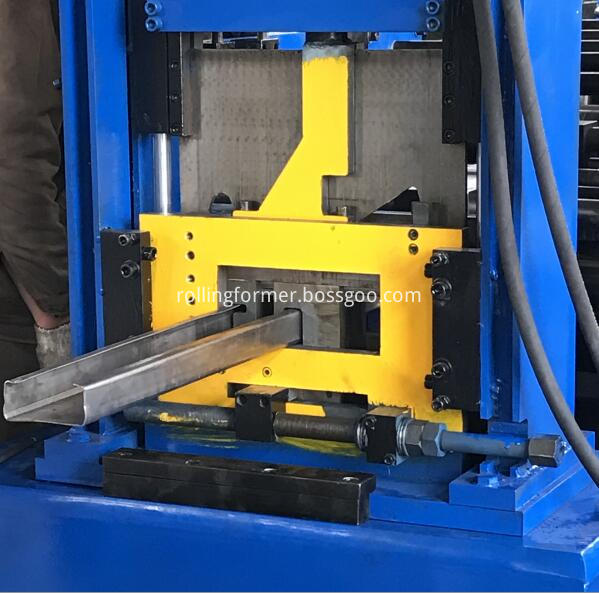

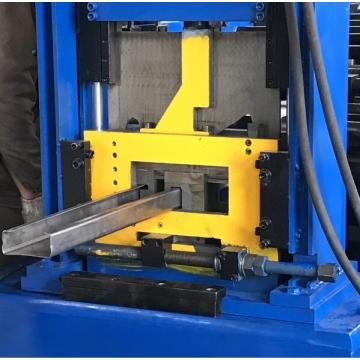

This is the adjustable cutting system, by this adjustable cutting system, you can cut any size you need, but no need to change the cutting blade. Just adjust the shaft left or right, up or down. This C section floor beam C purline machine cutting system is popular in the C purline roll forming machine.Easy to control, but with low cost.

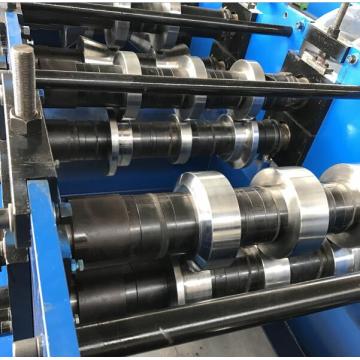

This is feeding system which can make the steel strips tidy and neat into the leveling rollers.There are two leveling rollers up and two leveling rollers down.

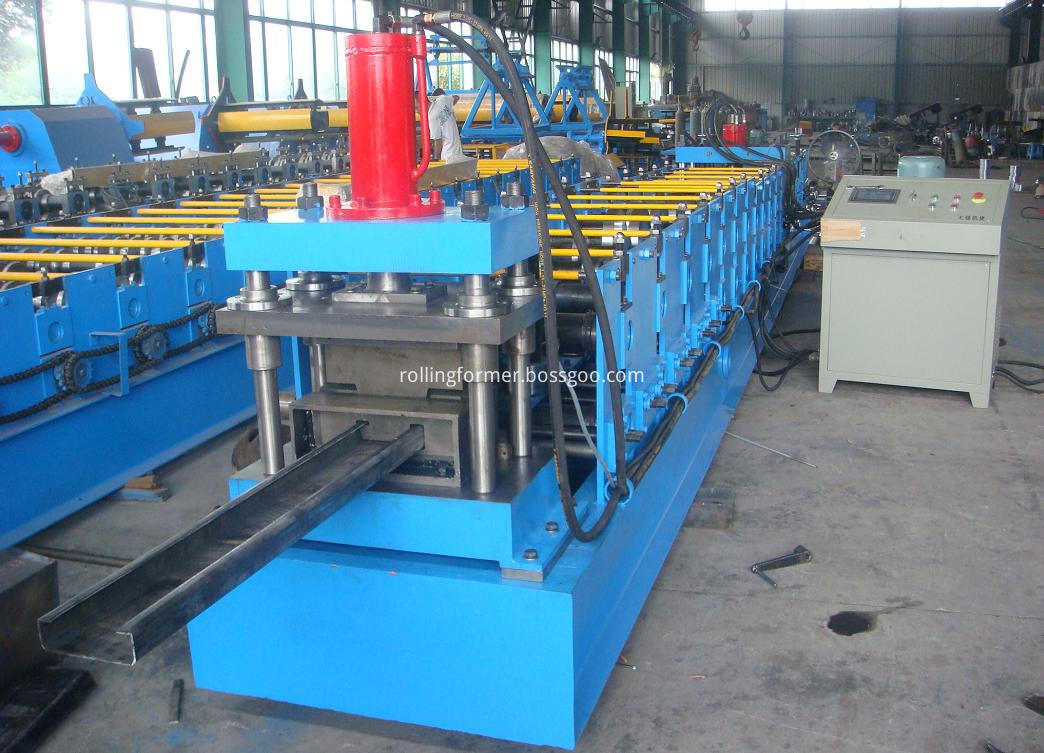

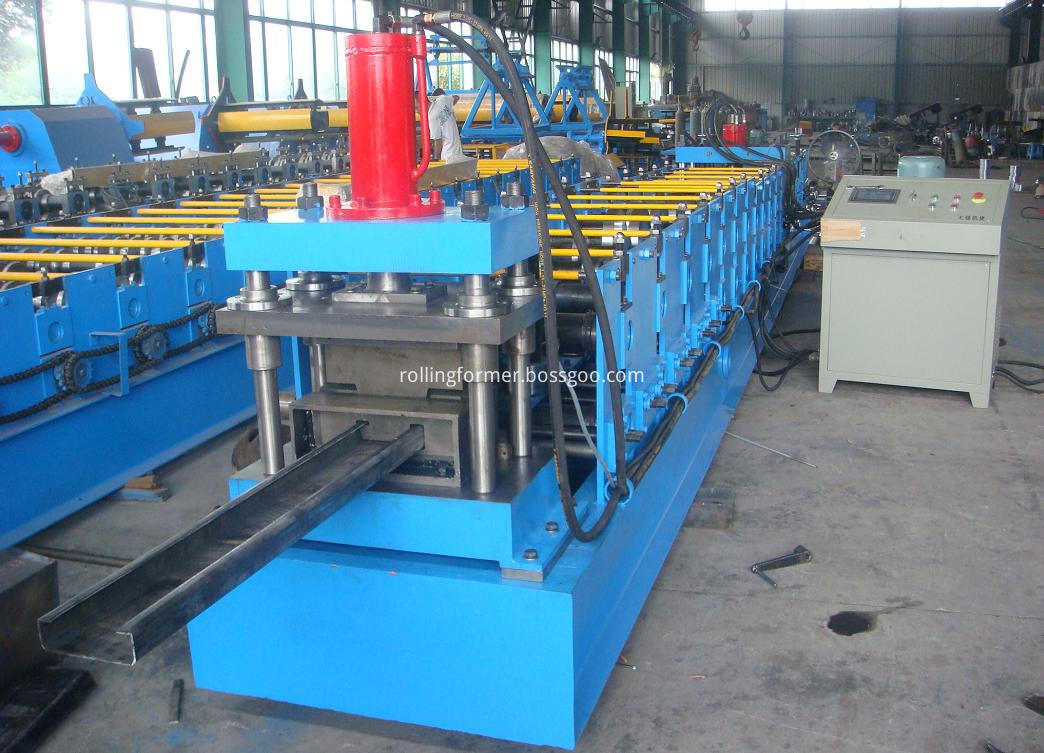

The material of the roller is Cr12 with finish machining after quenching by 56-65 degree tempeature.

The spacer on the shaft of the C purline roll forming machine is used to change the feeding width to form different size of the C purline floor beam.

The main motor system of the adjustable roll forming C Section Floor Beam rollformer.

This is the strong double chain of the adjustable roll forming C Section Floor Beam rollformer. This strong chain make the rollformer machine running stable and in good condition.

Below is some specification of the Main forming machine weight 6.5 Ton

Voltage 380V 50Hz (380 V is China normal voltage, but the voltage can be customize by customer.)

Method for fixing roller Memorial arch frame

Material of shafts 45# steel Thermal refining

Transmission method gear box

The main shaft material No. 45 steel quenching and tempering treatment

outer shaft diameter 80mm

Wheel material quenching process of GCr15 bearing steel HRC58-60

Roller 12 stations

The main motor power 15kw.

This machine is with good price, i will send you a offer to your Email, also some machine running videos to your Email or through whatsapp.

.png) Contact Now

Contact Now