Product Description

Tube rollformers induction welding tubes machine

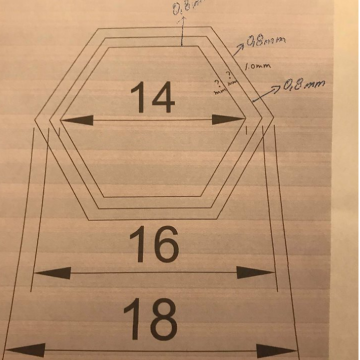

Tube rollformers induction welding tubes machine is used to making different sizes of tubes, the round tubes, the square tubes, the rectangle tubes, the hexagon tube and so on.

Normally the rollformers induction welding tubes machine sizes are as below: AP-25,AP-32,AP-50,AP-76,AP-127 and so on.

1 What size of the tubes can each Tube rollformers induction welding tubes machine make? Now let me give an example, For the AP-25 machine, it can produce the tube 9~Ф25.4mm x 0.25~1.2mm, For different shapes tube, such as round tube, square tube, rectangle tube, oval tube, hexagon tube and so on.,

2 Can one machine make different tube diameter tubes?

Yes, one Tube rollformers induction welding tubes machine can produce differents sizes of tubes by changing the molds and the clamps.

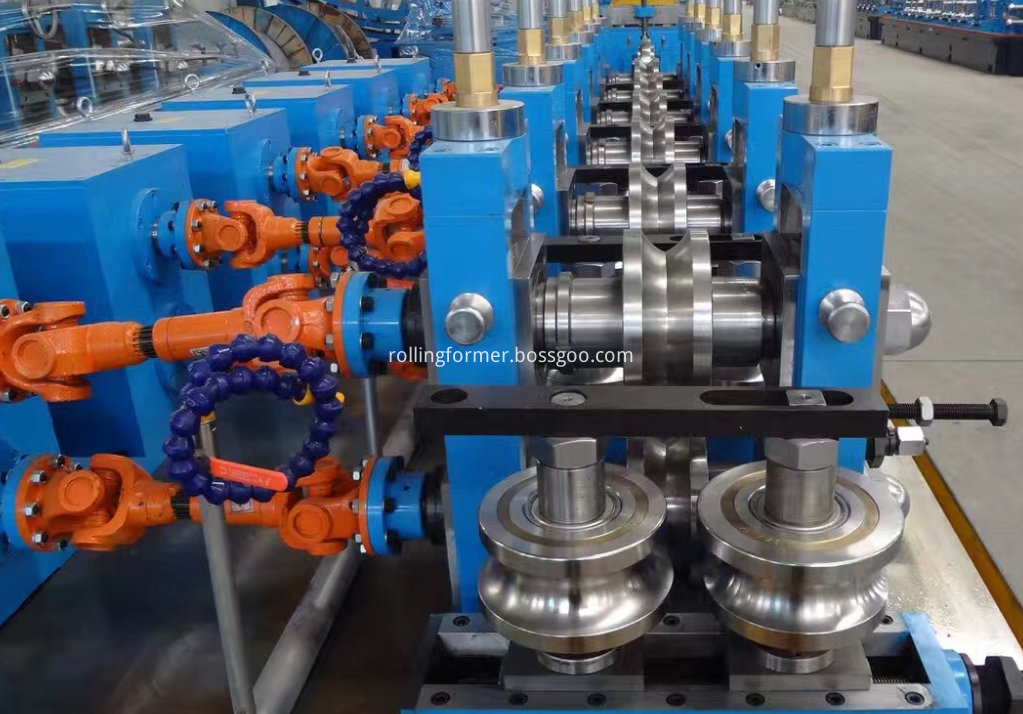

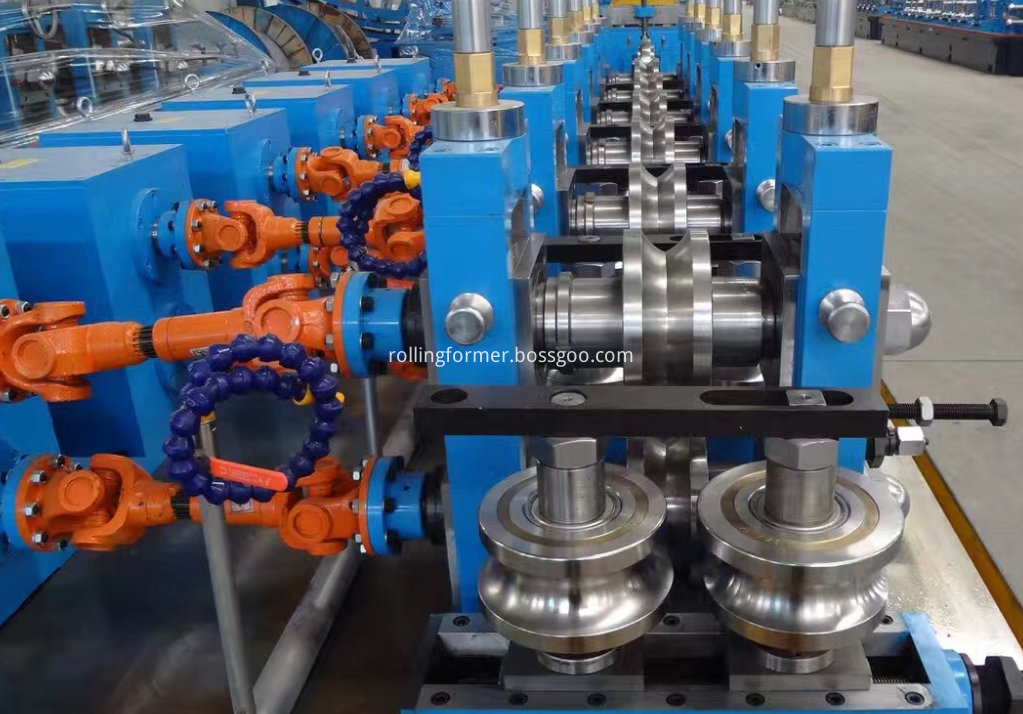

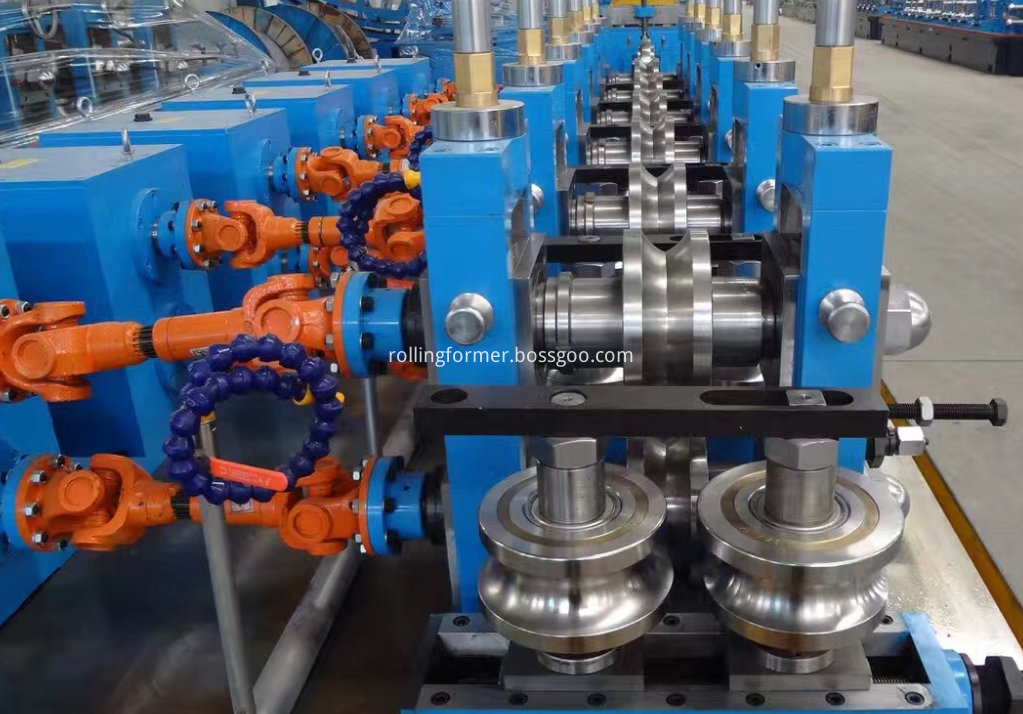

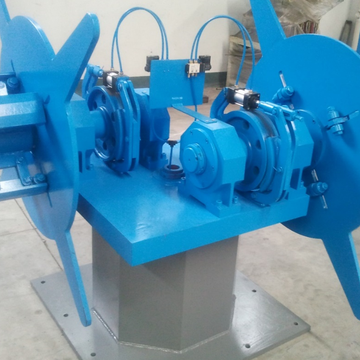

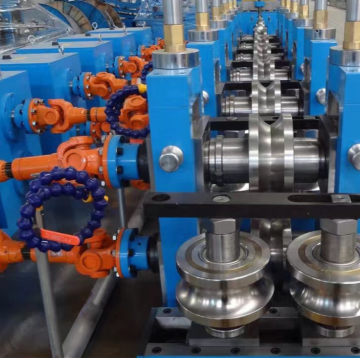

Below are pictures of the Tube rollformers induction welding tubes machine.

Tube rollformers induction welding tubes machine General processing is as below:

Steel Strip →→ Double-heads un-coiler →→Strip-head shearer & butt welder station →→Vertical cage accumulator →→Main driving →→ Forming M/C (Flattening unit + Breakdown section + Fin pass section + Seam guide unit + High frequency induction welding system+ Squeeze welding roller unit + Outside scrafing unit →→ Horizontal ironing stand) →→ Cooling section →→ Sizing M/C (Sizing section + Speed testing unit + Turk head straightener + Vertical pull-out stand) →→ NC hotsaw under computercontrol→→ Conveyor table

Double-heads Un-coiler

1.1 Type: Double stations, mandrel expansion by manual

1.2 Brake type: Pneumatic disk brake

1.3 Parameters:

- I.D of coil: Φ508mm (customized)

- O.D of coil: Max.Φ1800mm (customized)

- Coil width: 25~80mm

- Coil weight: Max. 2.0tone/coil

1.4 Mandrel expansion by manual:

- Expansion stroke: Φ420-Φ520mm

1.5 Mandrel Rotation type: By manual

Shearer & Butt Welder Station

2.1 Pneumatic shearer:

- Type Cutting by pneumatic system

- Strip width: ≤ 100mm

- Strip thickness: ≤1.2mm

2.2 Butt welder by manual

- Welder TIG-160A IGBT Or by A.C needle

- Input gas Argon gas as pure as 99.9%

Vertical cage

3.1 Type: Material folding cage, inner cage welded by steel flat bars

3.2 Width adjust by chain: 25~100mm

3.3 Strip thickness: 0.25 ~ 1.5mm

3.4 AC 2.2Kw motor with speed adjuster,double feeding rollers

3.5 Feeding speed: ≥200m/min

Forming & Sizing Mill

|

-

|

Forming and sizing section:

|

37Kw /1500rpm*1 set, with DC control box

|

|

|

-

|

Main gear decelerators:

|

ZLY type-Carbide-faced

cylindrical gear decelerators*1set

|

|

-

|

Drive to be Parker SSD-591

|

|

|

|

|

|

|

4.2

|

Forming section consists of:

|

|

|

-

|

Feeding & Flattening unit:

|

1 set

|

|

|

-

|

Driven stand:

|

8 sets (Horizontal)

|

|

|

-

|

Driven stand shaft:

|

Φ40mm

|

|

|

-

|

Material of shaft:

|

42CrMo (Surface quench,

grinding, 60 HRC ± 2)

|

|

|

-

|

Side roll stand:

|

8 sets(Vertical)

|

|

|

-

|

Side roll stand shaft:

|

Φ25mm

|

|

|

-

|

Material of shaft:

|

42CrMo (Surface quench,

grinding, 60 HRC ± 2)

|

|

|

-

|

Secondary gear box:

|

4sets

|

|

|

-

|

Universal joint:

|

8sets (16pcs)

|

|

|

-

|

Secondary gear box type:

|

Spiral bevel gear & Helical-spur gear

|

|

|

-

|

Material of spiral bevel gear :

|

20CrMnTi,HRC60±2

|

|

|

-

|

Material of helical-spur gear:

|

45#

|

|

|

-

|

Material of gear box:

|

35#, welded Plate

|

|

|

|

|

|

|

|

4.3

|

Solid State High Frequency Welder

|

|

|

4.3.1

Welding section consists of:

|

|

|

-

|

Seam guide unit:

|

1 set

|

|

|

-

|

Squeeze stand:

|

1 set (2pcs rollers)

|

|

|

-

|

Outside scarfing unit:

|

1 set (2pcs knives, clipped-type)

|

|

|

-

|

Horizontalunit for seam ironing:

|

1 set (2pcs rollers)

|

|

|

|

|

|

4.3.2 Cooling

section

|

|

-

|

Cooling method:

|

Shower & bath

|

|

-

|

Cooling tank length:

|

1.0M

|

|

|

|

|

|

4.3.3

High Frequency Solid State welder

|

|

-

|

Type:

|

GGP100-0.45-HC type high frequency induction welding

|

|

-

|

Normal output power:

|

100Kw

|

|

-

|

The rated DC power:

|

150Kw

|

|

-

|

Frequency range:

|

400-450KHZ

|

|

-

|

Cooling type:

|

air-water coolerfor welder, with glass fibre

tower

|

|

-

|

With air conditioner for inverter output

cabinet

|

|

4.4

|

Sizing

section consists of:

|

|

-

|

Driven stand:

|

6 sets (Horizontal)

|

|

-

|

Driven stand shaft:

|

Φ40mm

|

|

-

|

Material of shaft:

|

42CrMo (Surface quench,

grinding, 60 HRC ± 2)

|

|

-

|

Side roll stand:

|

6 sets(Vertical)

|

|

-

|

Side roll stand shaft:

|

Φ25mm

|

|

-

|

Material of shaft:

|

42CrMo (Surface quench,

grinding, 60 HRC ± 2)

|

|

-

|

Secondary gear box:

|

3sets

|

|

-

|

Universal joint:

|

6sets (12pcs)

|

|

-

|

Secondary gear box type:

|

Spiral bevel gear & Helical-spur gear

|

|

-

|

Material of spiral bevel gear:

|

20CrMnTi,HRC60±2

|

|

-

|

Material of helical-spur gear:

|

45#

|

|

-

|

Material of gear box:

|

35#, welded Plate

|

|

|

|

|

|

4.5

|

Speed testing roller

for NC hot saw

|

|

-

|

Type:

|

Touching pressure by air cylinder

|

|

-

|

Quantity:

|

1 set

|

|

-

|

Material of roller:

|

Cr12(ASTM-D3, SKD 1) Harden surface

|

|

-

|

Roller dia.:

|

Φ111.4mm

|

|

|

|

|

|

4.6

|

Turk head straightener with

single side rollers

|

|

-

|

Quantity:

|

2 sets, 4rollers/set

|

|

-

|

Material of roller shaft:

|

42CrMo (Surface quench, grinding, 60 HRC ± 2)

|

|

-

|

Roller shaft dia.:

|

Φ30mm

|

|

|

|

|

|

4.7

|

Vertical stand for

pull-out

|

|

-

|

Quantity:

|

1 set, 2rollers, Same as vertical stand

|

NC hot Saw under Computer Control

|

Type:

|

Friction

saw

|

|

Pipe OD:

|

Φ9 ~ Φ25.4mm

|

|

Pipe thickness:

|

0.25~1.2mm

|

|

Pipe length:

|

6m

|

|

Length Tolerance:

|

+/- 2mm

|

|

Motor for dolly drag:

|

DC 11Kw

|

|

Drag decelerators:

|

ZLY- Carbide-faced cylindrical gear

decelerators

|

|

Saw carriage travel:

|

Rack and pinion with gear lath

|

|

Motor for cutting:

|

AC4.0KW

|

|

Saw blade:

|

350*35*2.0*2pcs

|

|

Pipe clamp:

|

Pneumatic type, 2 sets

|

Conveyor table

|

Type:

|

Rollconvoyer

|

|

Structure:

|

Welding frame

|

|

Table length:

|

9meters

|

|

Driving of roll:

|

Chain with AC2.2Kwmotor

|

|

Speed adjust:

|

By AC inverter

|

.png) Contact Now

Contact Now