Product Description

Perforated shutter door roll forming machine

Perforated shutter door roll forming machine is professional making the shutter door slats for the door system. There are different types of shutter door slats, so Our factory design the shutter door roll forming machine according to shutter door slats sizes and thickness, with holes or without holes, with perforated holes punching or hydraulic connecting holes punching system. The shutter door roll forming machine cutting system can be hydraulic cutting system or saw cutting system, depending on the material of the shutter slats. We design the cutting system with high technolpgy, cut the shutter slats without burring.

Shutter doors with walls as play a role in the level

of separating. The shutter door is consists of the curtain plate, base bottom

shutter door plate, rail, bearing U channel, reel, box, control box, roll door,

stopper, lintels, manual switch means immediate release, push button switch and

13 parts safety device, etc.. Generally the shutter door is installed in the

wall separating the inconvenience of using the site. Shutter doors are widely

used for commercial facade, garage, shopping malls, hospitals, industrial

enterprises and other public places or homes. Especially used in large doorway

case , where it is inconvenient to install floor door convenience play, fast

turn on action.

The shutter door is divided by the opening way as

below:

1. The manual shutter door. With shutter slat on the

center axis of the torsion balance of power, to achieve the purpose of manually

pulling the shutter.

2. electric shutter door. Rotation with a special

motor to drive the shutter central axis, to shutter switch, when the motor is

rotated to set upper and lower limit stops automatically. Shutter doors for

motor are: Plug rolling door machine, O-Vol door, tubular roll door, fire door,

inorganic double curtain doors, rapid roll doors machines.

There are different varieties of the shutter doors,

such as ordinary shutter doors, wind shutter doors, fire shutter doors, fast

shutter doors, electric Australian (Mute) shutter doors

Shutter doors are almost always in the company or shop

shutter doors means, in fact, shutter doors in foreign countries have many

years of history, and also the last ten years, began to slowly introduce our

country, shutter doors have a good fire alarm function, high safety performance,

and many food and pharmaceutical industries are also using the warehouse to

isolate the shutter doors, shutter doors really visible place in terms of

security.

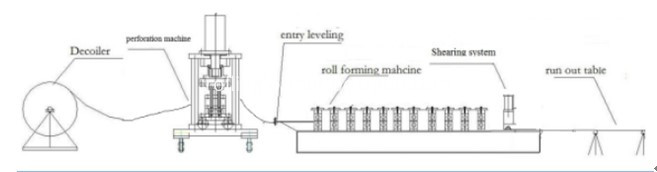

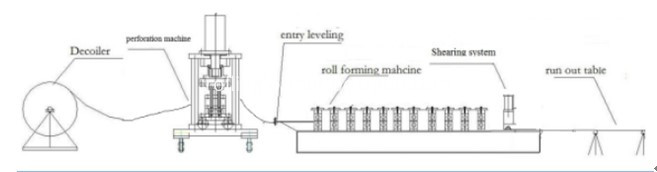

Process for the whole production line:

Decoiler --- perforation machine--- entry leveling----

roll forming machine---- shearing system--- run out table

The Perforated shutter door roll forming machine is

formed as below steps. The un coiler system to support the coil and then then

coil fed into the punching press machine to punching the holes on the shutter

doors. Then the strips with the holes will be fed into the entry mouth to be

leveled before into the roll forming machine roller stations. The main part of

the perforated shutter door machine is the rollers roll forming machine. The

feeding material will be bent little bu little by the rollers. There are about

10-15 rollers stations in the roll forming machine part. When the perforated

shutter door is formed and then will run into the shearing system.The machine

cutting system is controlled by the electric cutting system or the hydraulic

cutting system. When the shutter door is cut into required length, the shutter

door will be finished well and will be sent to the shutter door receiving

table.

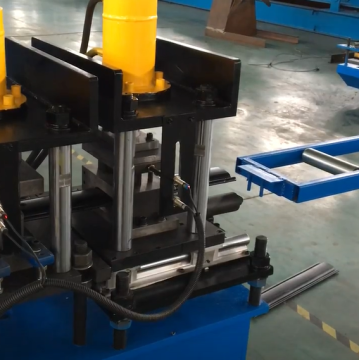

Below are some pictures of the machines:

Specifications of the shutter door is as below:

Specifications Production U

Forming steps 14

Memorial arch Frame Thickness 30 mm

Shaft diameter 50mm

roller material Cr12Mov

shaft material # 45 steel

Work speed 5-15 meters/min

Transport Gear transmission and chain transmission

Type of cutting Servo tracking high speed cutting

Cutting tolerance ±1mm

Main Power 5.5 kw

Cutter Cr12Mov

Voltage 380 V(As customer's requirements)

Cutting system of the shutter door rollformers

Function Automatic cutting controlled by PLC. It adopts the Servo tracking cutting and automatic location to decide the dimension and cut the target products.

Material of blades Cr12Mov

Power supply Hydraulic power

Components It contains one set of blade, one hydraulic tank and one cutter machine.

Servo Motor Power 1.2 kw

Feature Ensure stability, precision and cutting speed

Stroke switch non-contact photoelectric switch

Our factory is professional make the rollformer machines for the steel roofing, CZ purlines, steel framing strut, suspended ceiling channel, cable tray roll forming machine, shutter door rollformers, door frame rollformers, ridge cap roll forming machines and so on. If you need any machine , pelase feel free contact me, please!

we can design the machines according to your requirements!

.png) Contact Now

Contact Now