Product Description

Heavy duty Gearbox transmission bolting Rafted rollformer

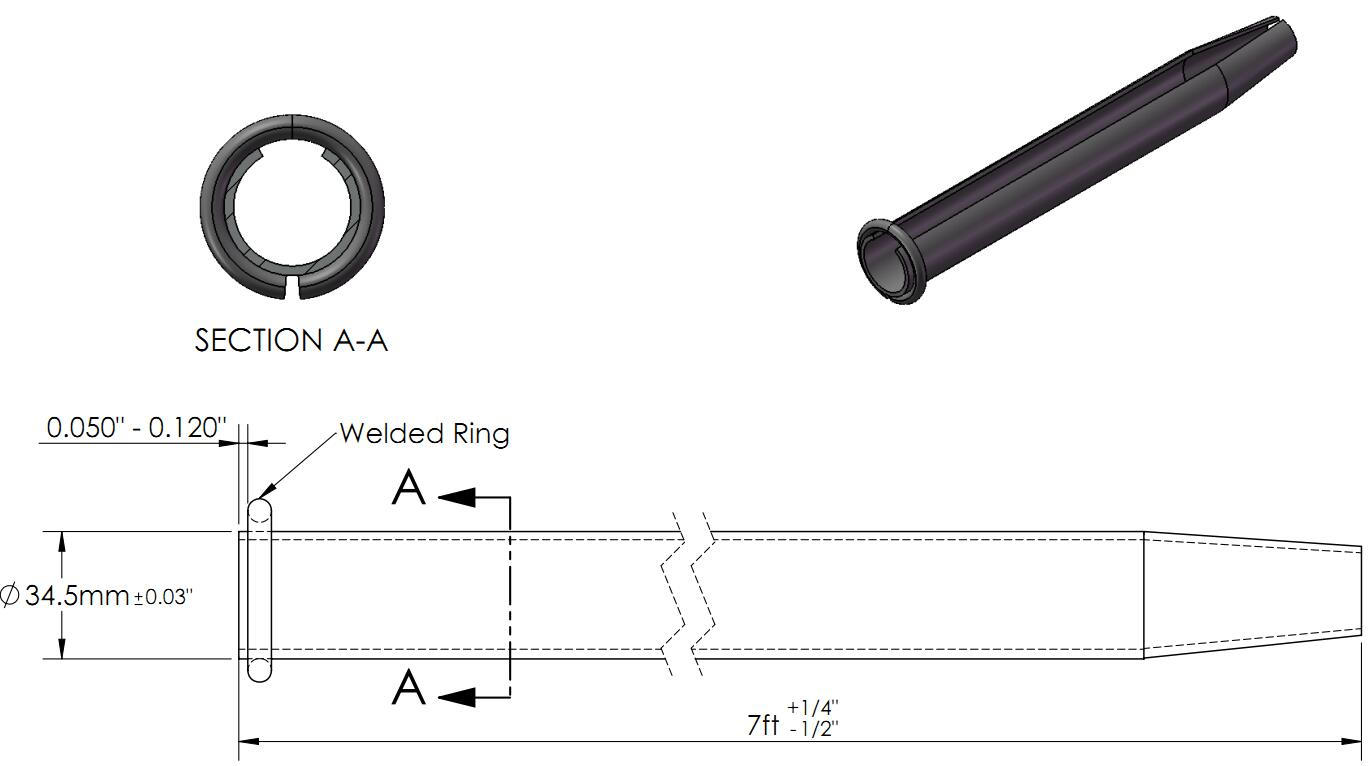

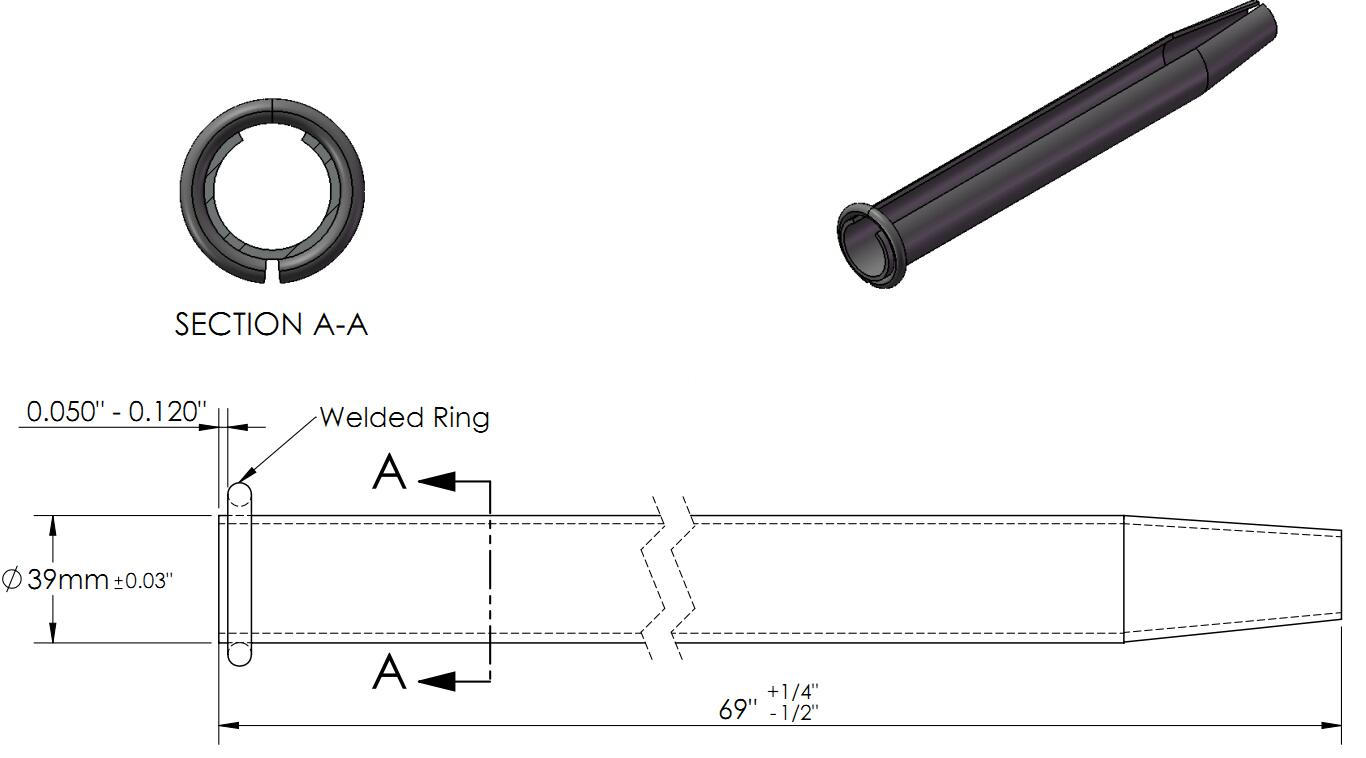

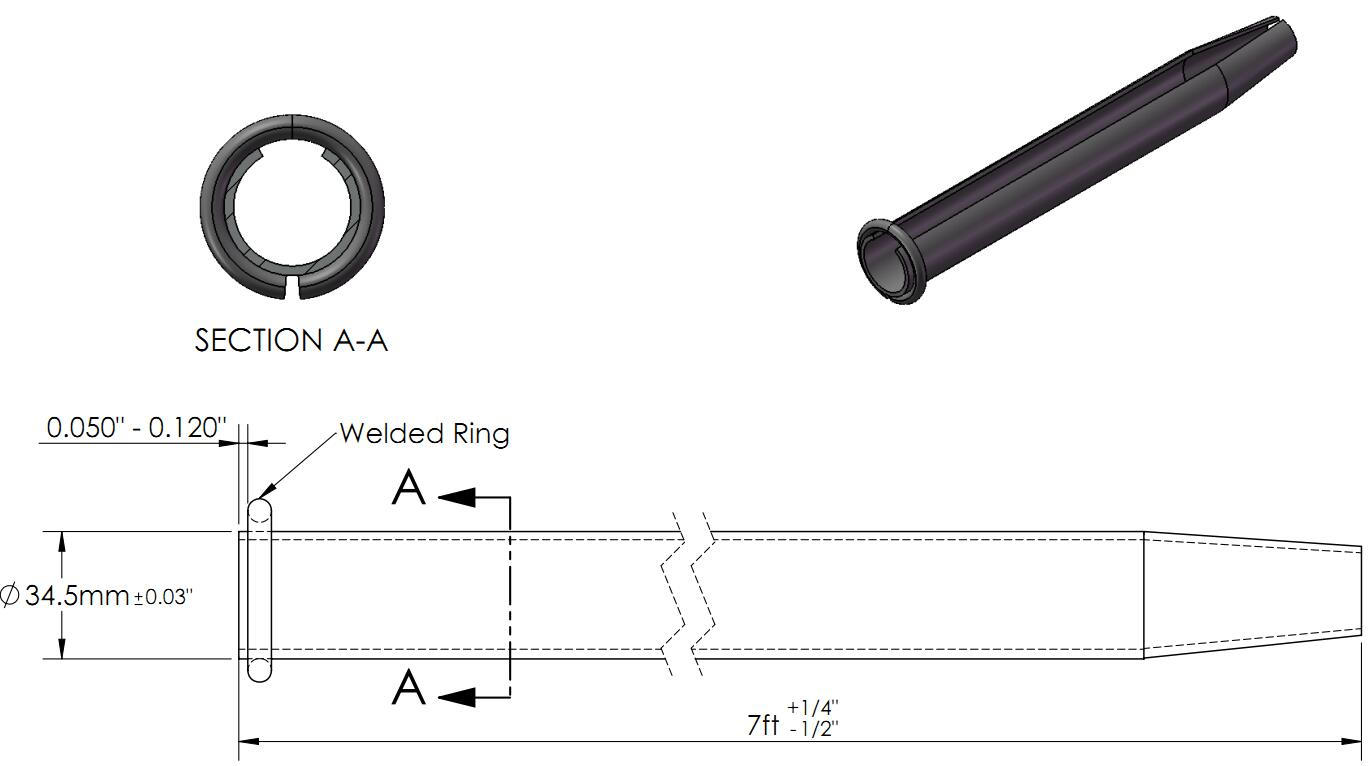

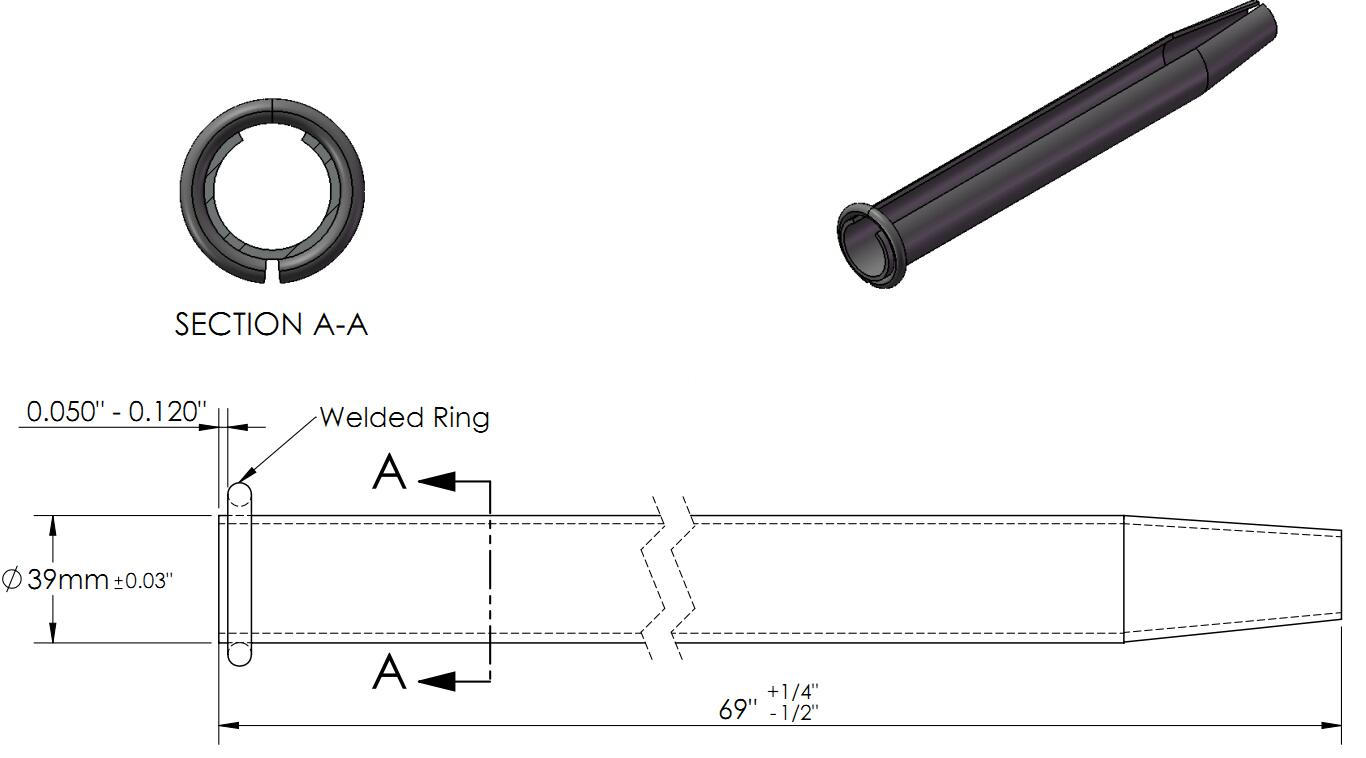

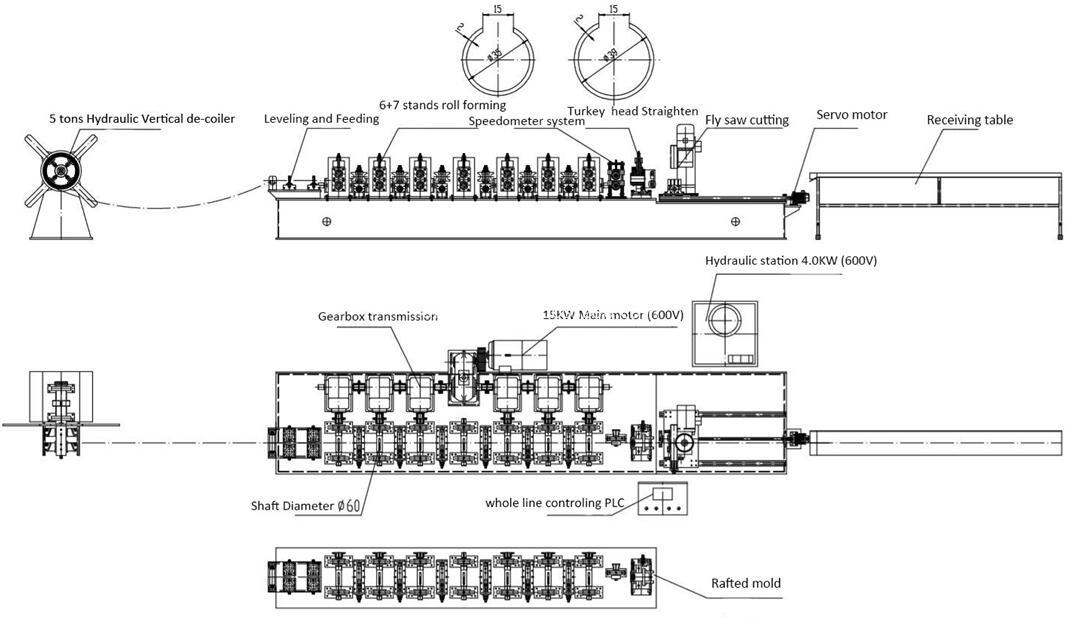

Heavy duty Gearbox transmission bolting Rafted rollformer can produce the steel friction rock bolts for sizes of 33mm(1-19/64").35mm(1-3/8").39mm(1-1/2").46mm(1-13/16"), thickness with 2mm-4mm. also with the steel bolts necking, and metal bolts notching. The steel bolts are with high strength steel and avaiable in different diameters and length, and available for using in corrosive environments. The friction rock bolts are made from high strength steel, such as HSLA 60. The friction bolts are available in galvanized steel and stainless stell, increasing capacity for prectecting from corrosion.

Heavy duty Gearbox transmission bolting Rafted rollformer is designed with gearboss transmission, high capacity, 1000 feet per minute.

Heavy duty Gearbox transmission bolting Rafted rollformer is designed to produce the steel bolts in high capacity, the speed can reach 100 feet per minute. Steel bolting rollformer friction bolts rollformer line is designed with the function of processing the bolts including: rollforming, cutting,necking,notching,automatic stacker and packing.

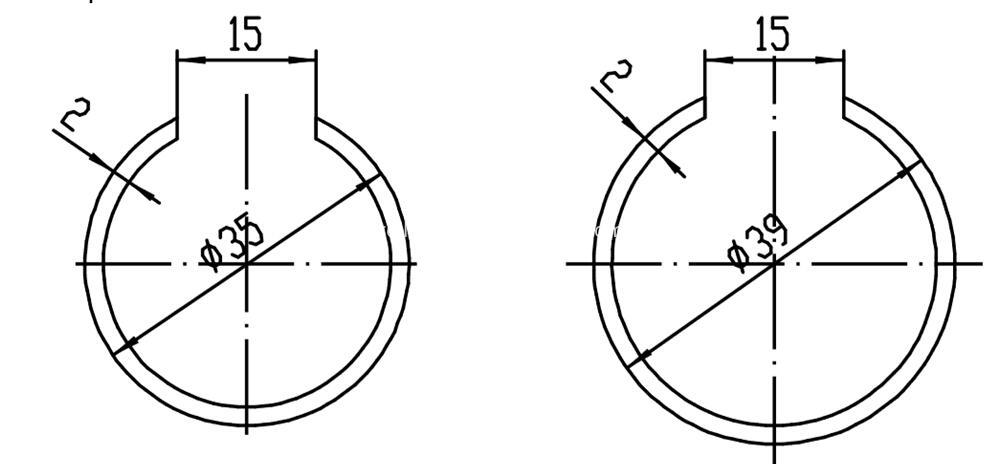

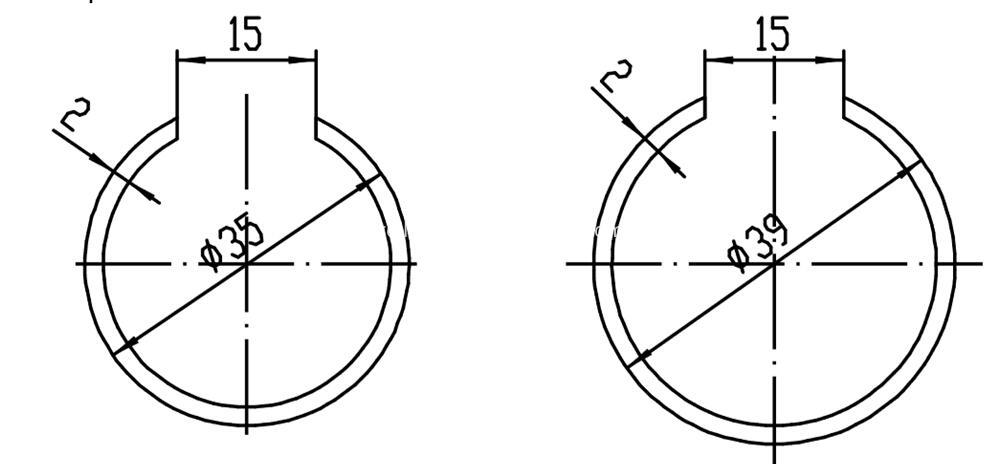

Whole line of Steel bolting rollformer friction bolts rollformer line

including below parts: 35 mm friction bolts Rafted molds (14 stands) 1 set

Friction bolts 39 roll former 5 tons Hydraulic de-coiler 1 set

Leveling and Feeding system 1 set

Hydraulic notching system 1 set

roll forming machine (14 stands) 1 set

Speedometer system 1 set

Turkey Straightening system 1 set

Fly saw cutting 1 set

Hydraulic station 1 set

PLC controlling cabinet 1 set

Receive table 2 sets

Working Process:

Hydraulic Vertical decoiler-Levelling feeder-7 Horizontal stands + 6 Vertical stands roll forming-Speedometer system-Turkey Straightening system –Servo motor tracking fly saw cutting-Receive table- Hydraulic notching machine

5 Ton Hydraulic Decoiler Usage: It is used to support the steel coil and uncoil it in a turntable way.

Passive uncoil pulled by roll forming system

Loading capacity: 5 T

Inner diameter: 508--610mm

Size: 4500х1800х1400

Weight t: 6 tons

Voltage:600V 50HZ 3Phase

Roller fixer : Vertical arch

Frame : Memorial arch frame type

Frame thickness:25mm

Drive mode: Gearbox transmission

Material of rollers: GCr12MoV

Material of shafts: 45# steel with tempering

Diameter of shafts: φ 60mm

Number of rollers : 13 rollers (7 Level, 6 Vertical)

Main power: 15kw 600V

Cycloidal planetary gear speed reducer)

Speed: 30m/min (Including fly saw cutting)

Steel bolting rollformer friction bolts rollformer line for the size of 33mm, 35mm, 39mm, 46mm, by adjusting and changing the molds, it takes about 1.5 hour. also can be designed as with rafted rollformer, it talkes 20-30 minute to finish this.

Machine features:

1. The speed of this speed line is 100 feet/min.

2. This rollformer can produce 2 sizes of the bolts, with rafted molds system.

3. This rollformer is designed with arch pillar structural, and gearbox transmission, so that the machine is strong to work stable.

4. This rollformer line is a heavy euipment, we use the best parts for the machine for durable working.

Below is the cutting system of the friction bolts rollformer, it is high speed fly saw servo cutting system.

Servo motor fly saw

cutting system

Material

of blades: Gcr12MoV quenched

Power

supply : hydraulic power

Frame :

Pillar style with rack & pinion system

Stroke

switch : non-contact photoelectric

switch

Components: It contains one set of cutting tools, one

hydraulic tank and one cutter machine.

Hydraulic motor Power: 4.0kw

Hydraulic oil: 46#

Components: The system includes a set of hydraulic

tank, a set of hydraulic oil pump, and two hydraulic pipes. And two sets of

electromagnetism valves.

If you want to know more about the Heavy duty Gearbox transmission bolting Rafted rollformer, please feel free contact me, please!

Our factory is professional design and manufacturer the rollformers for different profiles. The steel bolting rollformer friction bolts rollformer line,round tube roll forming machine, square tube roll forming machine, CZ purline roll forming machine, metal roofing roll forming machines, shutter door roll forming machine, garage door panel roll forming machine, cable tray roll forming machine, door frame roll forming machine, and other fields roll forming machine, for example, the automobile V band calamp roll forming and bending machine, elevator guide rail roll forming machine, and so on.

If you need any machine, kindly let me know your profile size, thickness, and drawing, i will send you the designing machine and offers, some machine running vidoes for your reference!

If you do not have any information, you are free to contact me, i will send you some drawing for your rference!

My whatsapp: 0086 13151186226

.png) Contact Now

Contact Now