Product Description

Decking panel roll forming floor decking machine

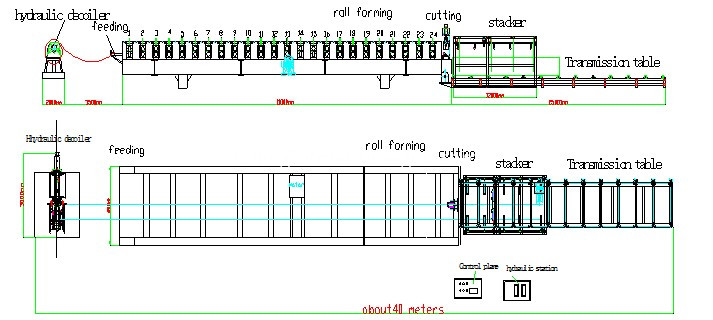

Floor decking metal sheet is widely used in modern building, instead of the concrete decking sheet. steel composite floor decking sheet rollforming line produce the metal decking by roll-formed procession. The floor decking machine is designed with the manual decoiler, the leveling system, embossing rollers and main roll forming machine rollers, and hydraulic cutting system, decking receiving system, Besides, included in a whole like floor decking machine floor deck roll forming machine, there are controling cabinet and hydraulic stations too.

Steel composite floor decking sheet rollforming line floor deck making machinery for cutting floor boards CNC automatic machines, plate-type high-strength galvanized steel floor panels, large-span floor shop contained cement. PLC control, touch screen operation, easy to understand. Greatly improve the efficiency, quality and cheap, affordable and reasonable new brilliant product design, in line with market demand.

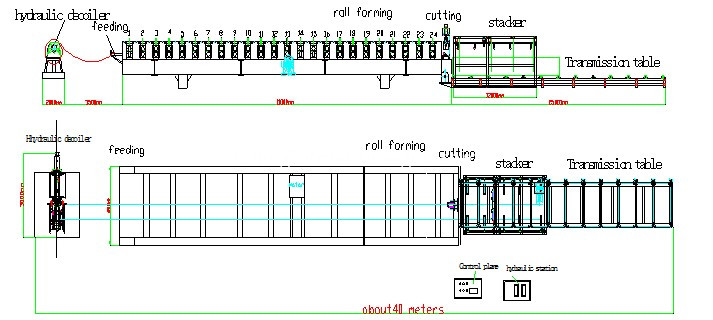

Steel composite floor decking sheet rollforming line Processing flow diagram of machine

Manual decoiler →Feeding material into machine →Roll forming machine →Measure length →4 sets butt welding machine→Straightening→Hydraulic cutting →Finished Products

Processing material: colored steel plate, galvanized plate, or aluminum plate Material thickness: 0.8---1.2mm

Material hardness: 195 mpa---350 mpa

Material width: 1000mm

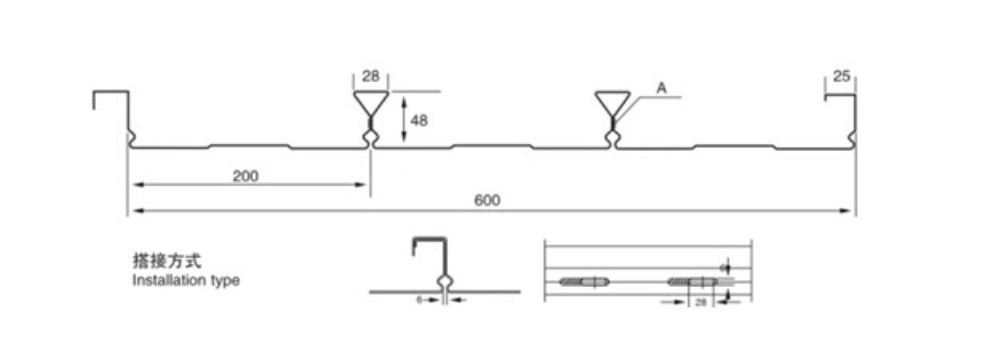

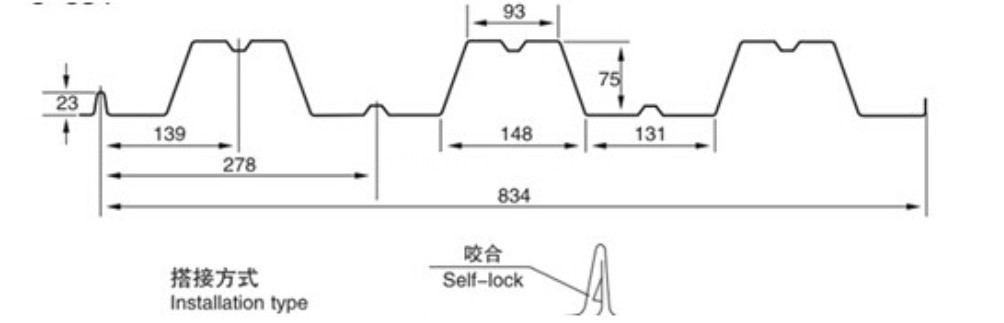

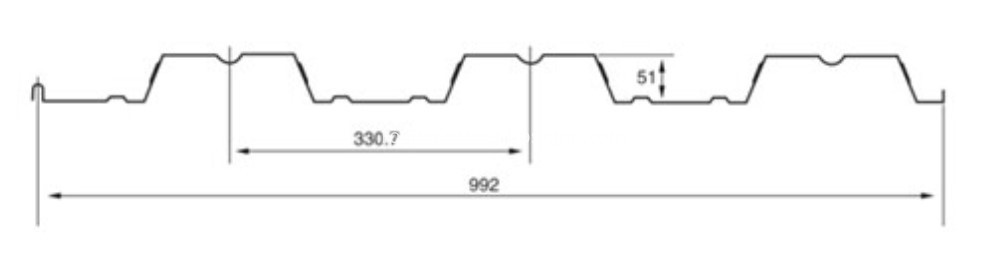

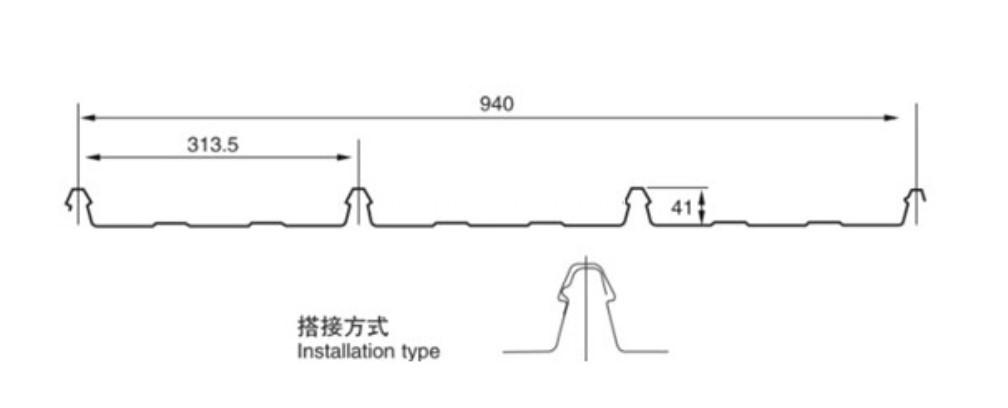

Formed width: 720/960mm

Wave length: 187.5mm

Step height: 75mm

Step length:150mm---380mm(adjustable)

Forming speed: 8-10m/min

Entry Beach

Usage:Put the raw material(steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron.

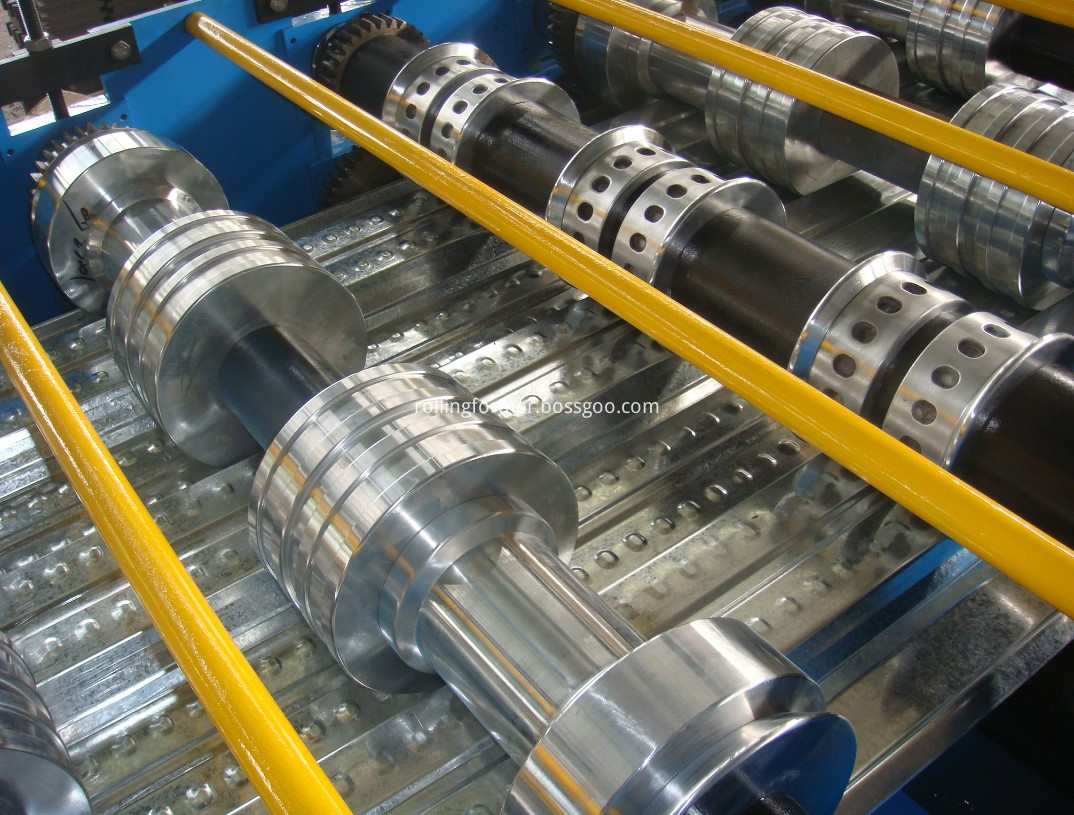

Main Roll Forming System

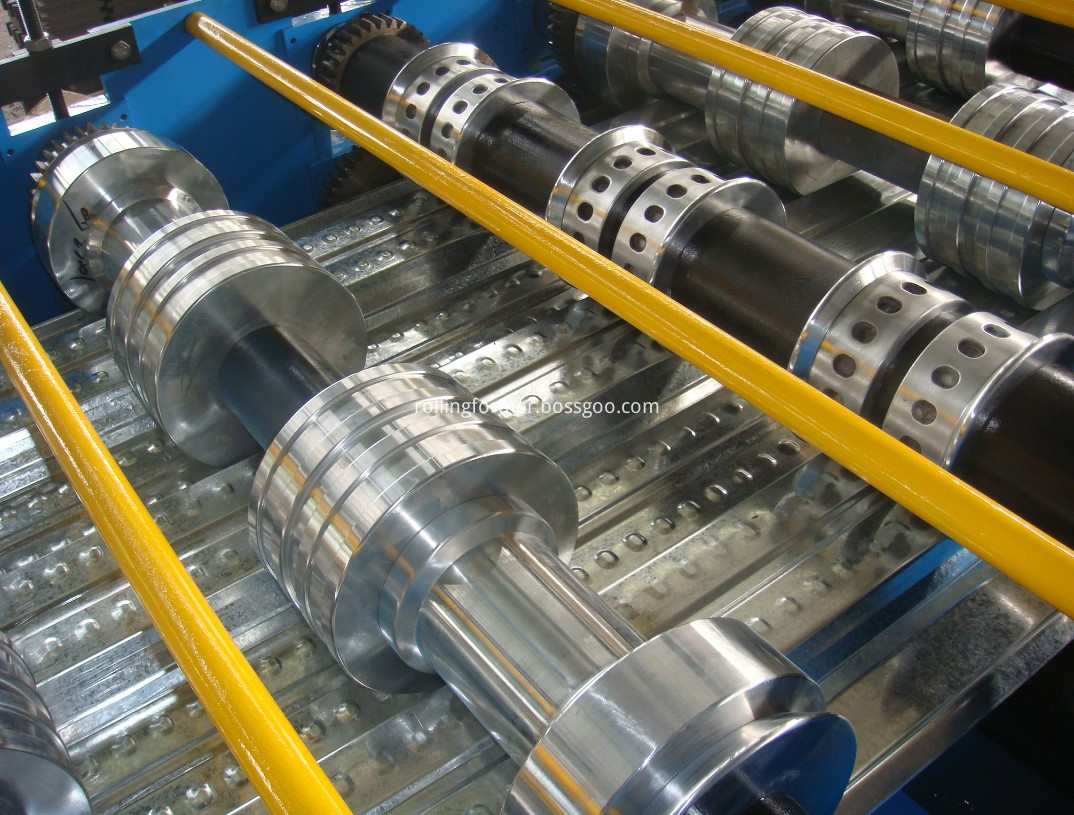

Feature : Ensure stability , precision and lifetime.

Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, chain transmission ,roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is being stamped.

Length of the main part: about 16000 х1650 х1500

Weight of main part:

Voltage : 380 V/50HZ 3Phase or as your required

Roller fixer : middle plate

Frame : 400 H steel welded

Drive mode: chain

Material of rollers:45# steel, surface hard chromium plating.

Material of shafts: 45# steel

Diameter of shafts: φ 80mm

Number of rollers : 36rollers

Main power: 2X11 kw

Shearing Mechanism

Feature : Ensure stability, precision and cutting speed

Function : Automatic cutting controlled by PLC

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

Material of blades: C r12 quenched

Power supply : hydraulic power

Components:It contains one set of blade , one hydraulic tank and one cutter machine.

Hydraulic Station

It is controlled by gear pump. After filling the hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job.

Power: 5.5kw

Hydraulic oil: 46 #

Electric Control System

Feature:

1. Adopted PLC , frequency converter , Delta touch screen from Taiwan to ensure high speed with stability, precision and lifetime.

2. Other electric element are Panasonic

Counter

One counter gauges length, pulses, and decides length.

Omron encoder for length measurement.

Products receiving tables

It adopts welded steel and supported roller to transmit the products.

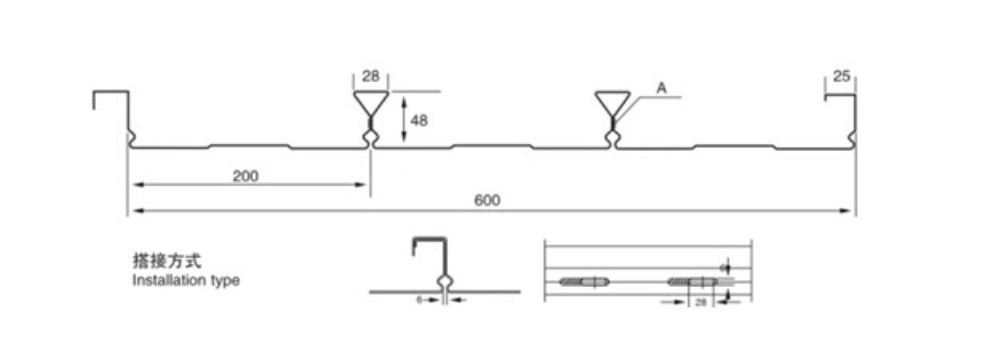

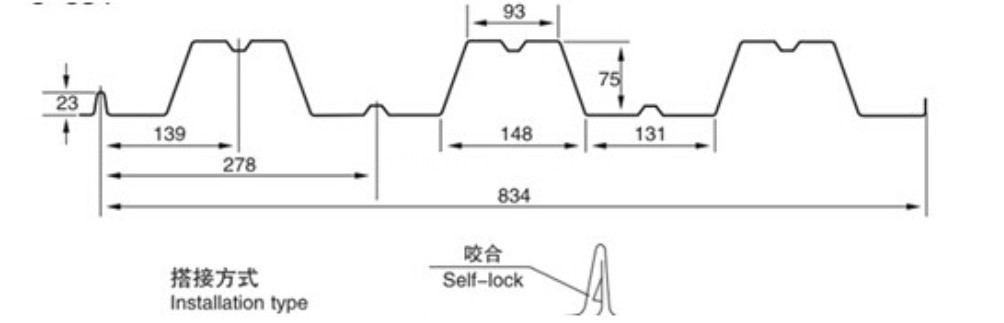

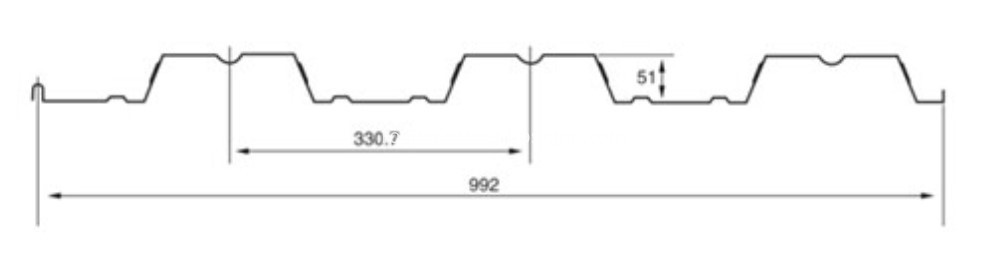

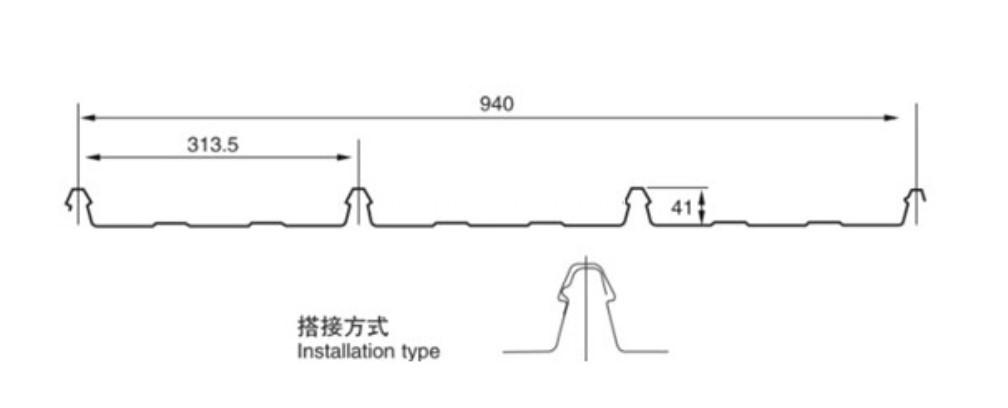

Below are the pictures of the embossing rollers of the steel composite floor decking sheet rollforming line

Our factory is professional make the steel composite floor decking sheet rollforming line, Metal roofing sheet rollformers, CZ purline roll forming machine, floor decking machine, steel framing CU stud and track roll forming machine, corner bead L angle roll forming machine, metal tube round pipe, square pipe rollforming machine, high frequency tube welding machine, shutter door slats rollformers, shutter door U guide roll forming machine, and door frame roll forming machine, door panel making machine,Automobile V band clamp forming and bending machine, elevator guide rail roll forming machine, and shelving racking roll forming machine, the cable tray roll forming machine, and different special profile roll forming machine. we can design the machine according to your drawing. If you need any roll forming machine line, just feel free contact us, we can design the machine and send you the offer in first time!

Our factory is professional make the rollformer machines for the steel roofing, CZ purlines, steel framing strut, suspended ceiling channel, cable tray roll forming machine, shutter door rollformers, door frame rollformers, ridge cap roll forming machines and so on. If you need any machine , pelase feel free contact me, please!

we can design the machines according to your requirements!

.png) Contact Now

Contact Now