Product Description

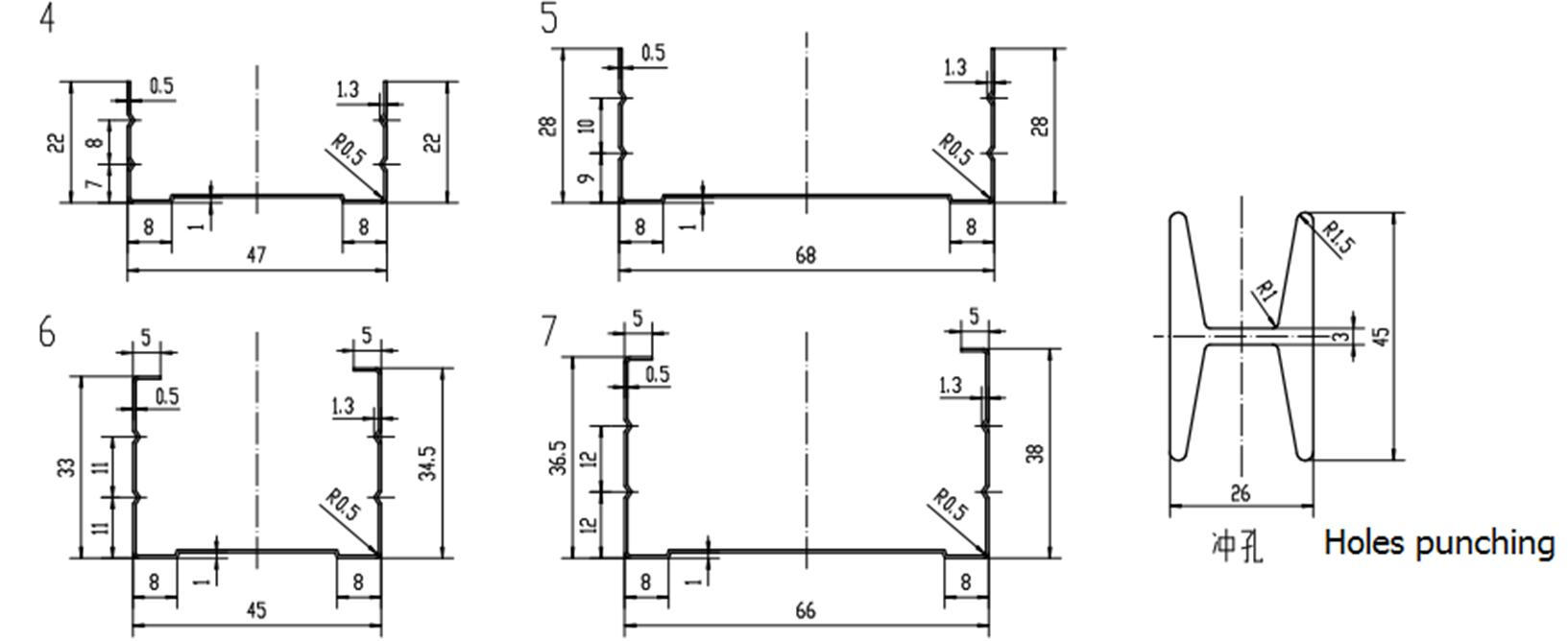

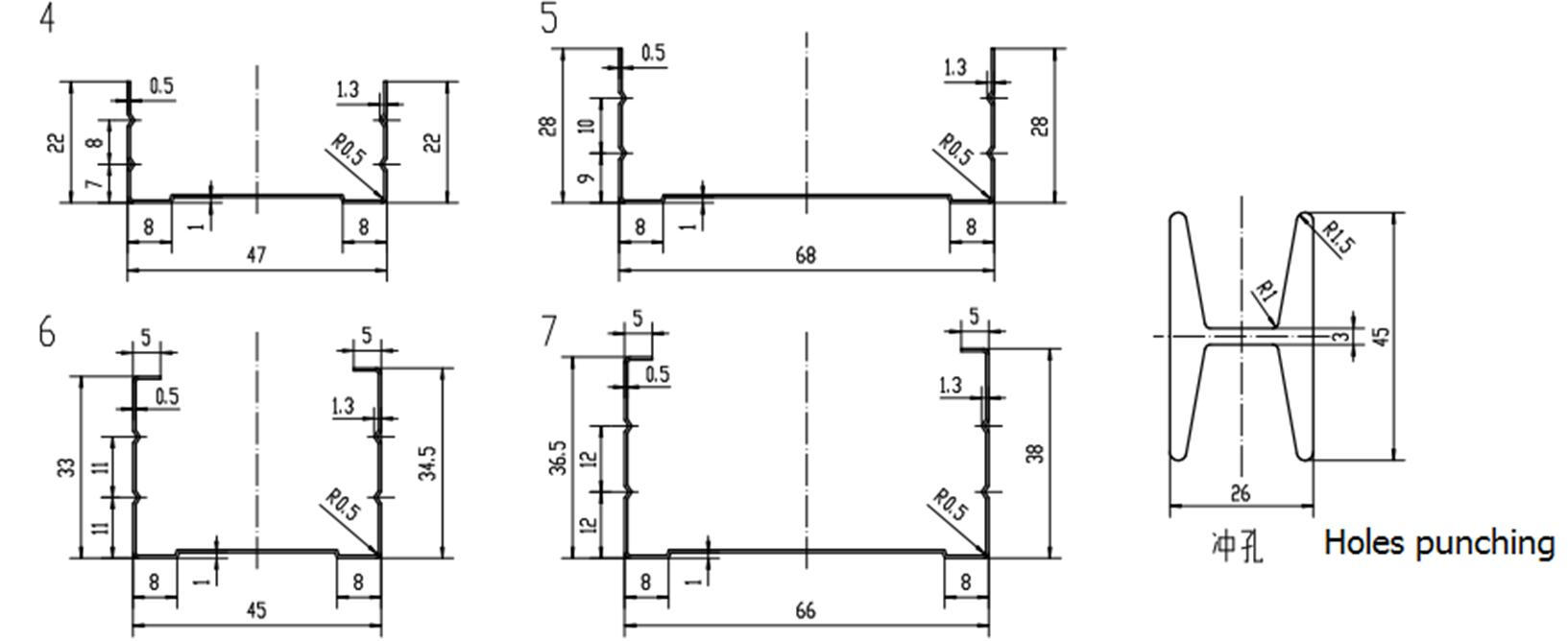

45/66 C 47/68 U Roll Forming Machine

45/66 C 47/68 U Roll Forming Machine adopts CNC controling system, full line 45/66 C 47/68 U Roll Forming Machine is automatic running. 45/66 C 47/68 U Roll Forming Machine cutting device adopts the servo motor high speed cutting system. 45/66 C 47/68 U Roll Forming Machine can produce C studU track steel framing for suspended ceiling system, and drywall steel framing system. For the C stud and U track, it can be designed with punching holes device, punching logo device, high speed fly saw cutting device, and automatic receiving table system.

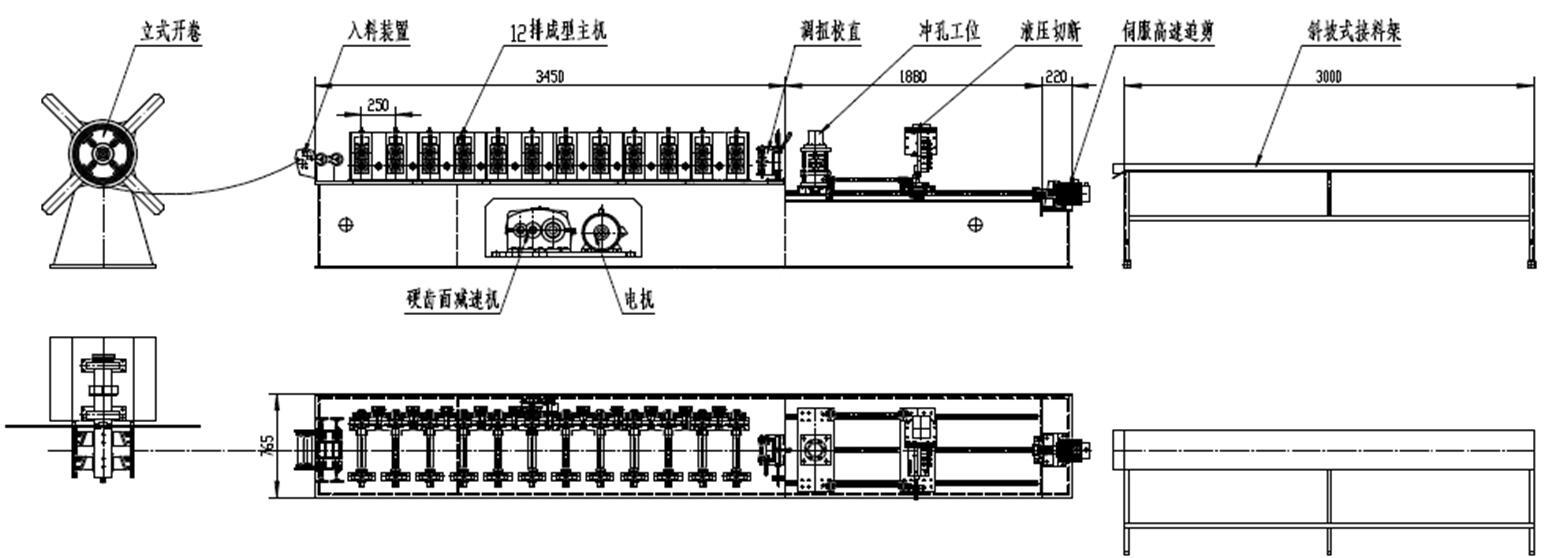

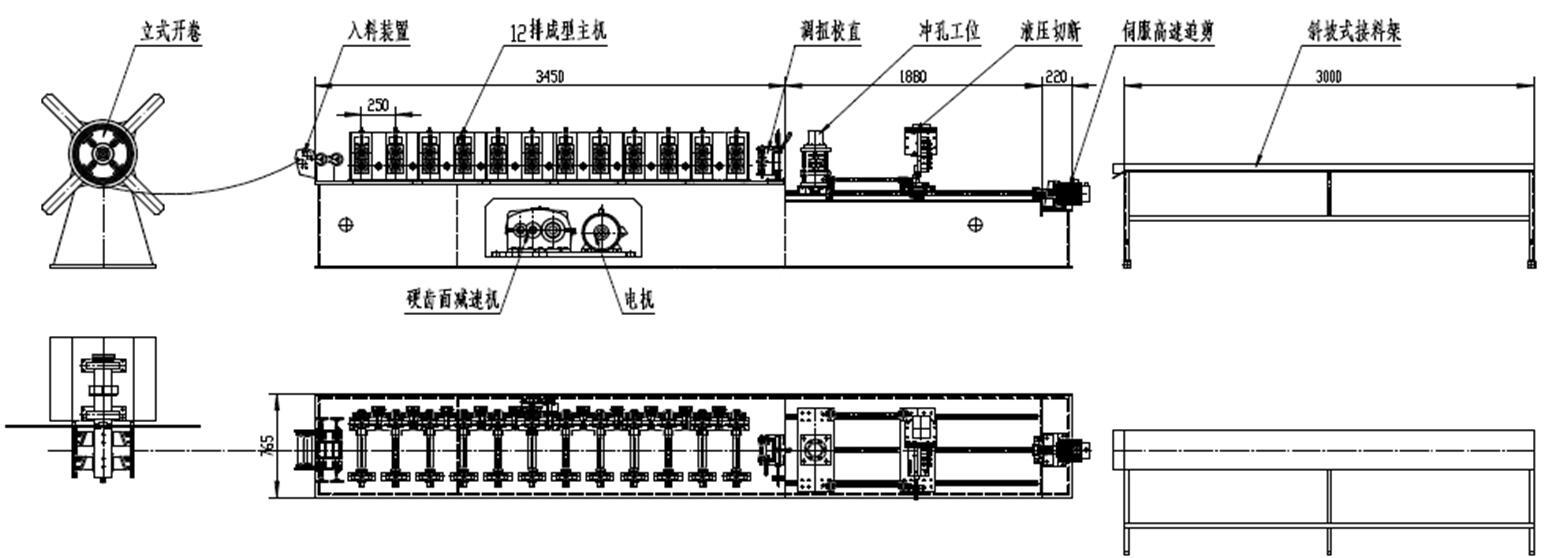

45/66 C 47/68 U Roll Forming Machine whole line including below parts:

Hydraulic/manual decoiler,leveling system, feeding and punching holes,main roll forming machine,hydraulic cutting system and receiving system.

45/66 C 47/68 U Roll Forming Machine specifications as below:

Hydraulic Uncoiler

Inner Diameter 450-550 mm

Max coil out diameter max 1500mm

Max coil width 300mm

Carrying capacity 2 T

45/66 C 47/68 U Roll Forming Machine Entry Beach

Put the raw material (steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of the localization guidance. it can guarantee that the products are neat, parallel and everything is uniformity

45/66 C 47/68 U Roll Forming Machine Main forming machine

Specifications Production C U

Forming steps 12 rollers

Memorial arch Frame Thickness 35 mm

Bearings Double bearings

Shaft diameter 50mm

roller material Cr12Mov

shaft material # 45 steel

Hardened reducer ZLY-160

Work speed Without punching 0-40 meters/min

With punching 0-30 meters/min

Transport Gear transmission and chain transmission

Type of cutting Servo tracking high speed cutting

Cutting tolerance ±1mm

Main Power 11 kw

Cutter Cr12Mov

45/66 C 47/68 U Roll Forming Machine Cutting system:

Feature Ensure stability, precision and cutting speed

Function Automatic cutting controlled by PLC. It adopts the Servo tracking cutting and automatic location to decide the dimension and cut the target products.

Material of blades Cr12Mov

Power supply Hydraulic power

Components It contains one set of blade, one hydraulic tank and one cutter machine.

Servo Motor Power 2.3 kw

Punching holes H holes punching system

Feature Ensure stability, precision and cutting speed

Cutting blade 4 sets

Stroke switch non-contact photoelectric switch

45/66 C 47/68 U Roll Forming Machine Hydraulic stations:

Double motor Hydraulic Station Power 3 kw + 3.0 kw

Hydraulic oil 46#

Components The system includes a set of hydraulic tank, a set of hydraulic oil pump, 2 hydraulic pipes. And 1 set of electromagnetism valves.

Feature With wind cooling heat dissipation system

Our factory is professional making the steel framing machine, suspended ceiling channel C stud and U track rollformers, CZ purline rollformers, metal roofing sheet roll forming machine, cable tray roll forming machine, steel framing strut roll forming machine and other rollfoming equipments. We can design the machine according to your profile shape, drawing, thickness, and material, and any customed requirements.

If you want to know more about our roll forming machines, please feel free contact me, please!

.png) Contact Now

Contact Now