Product Description

41x41 unistrut metal framing roll forming machine

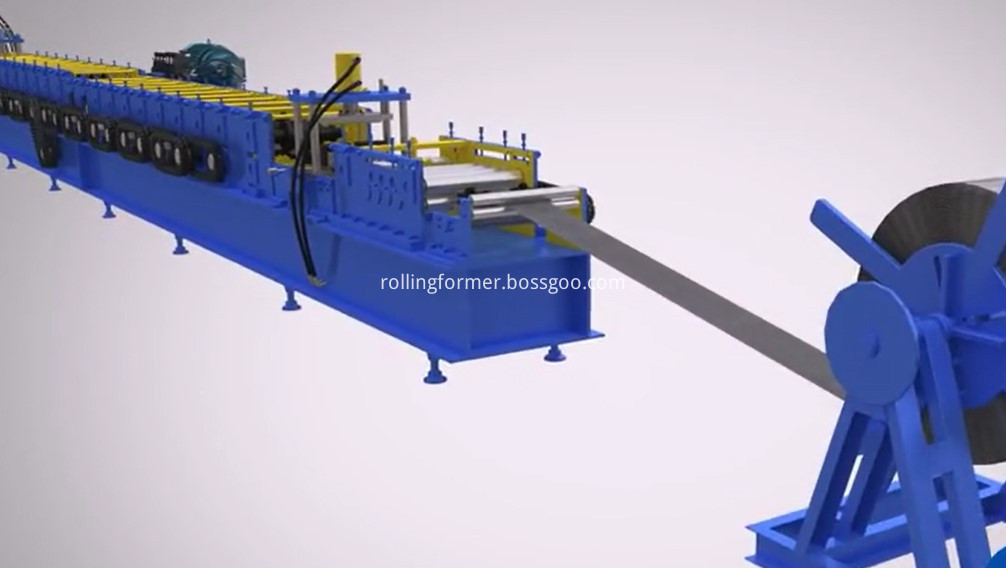

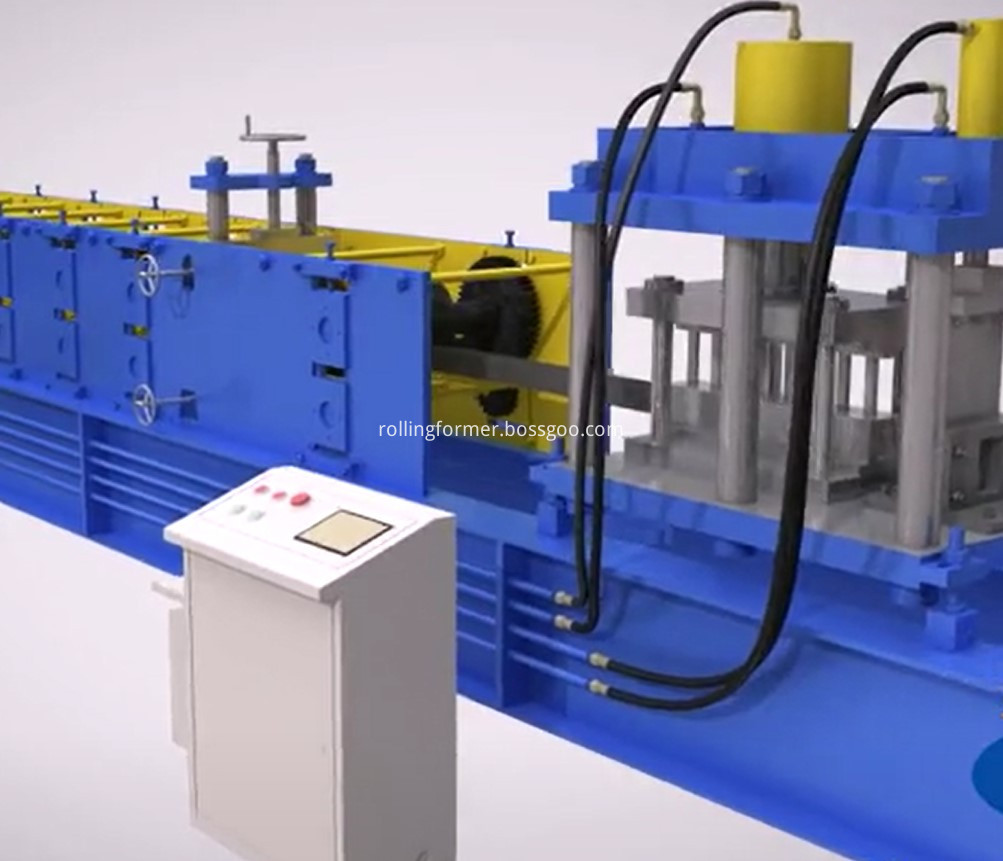

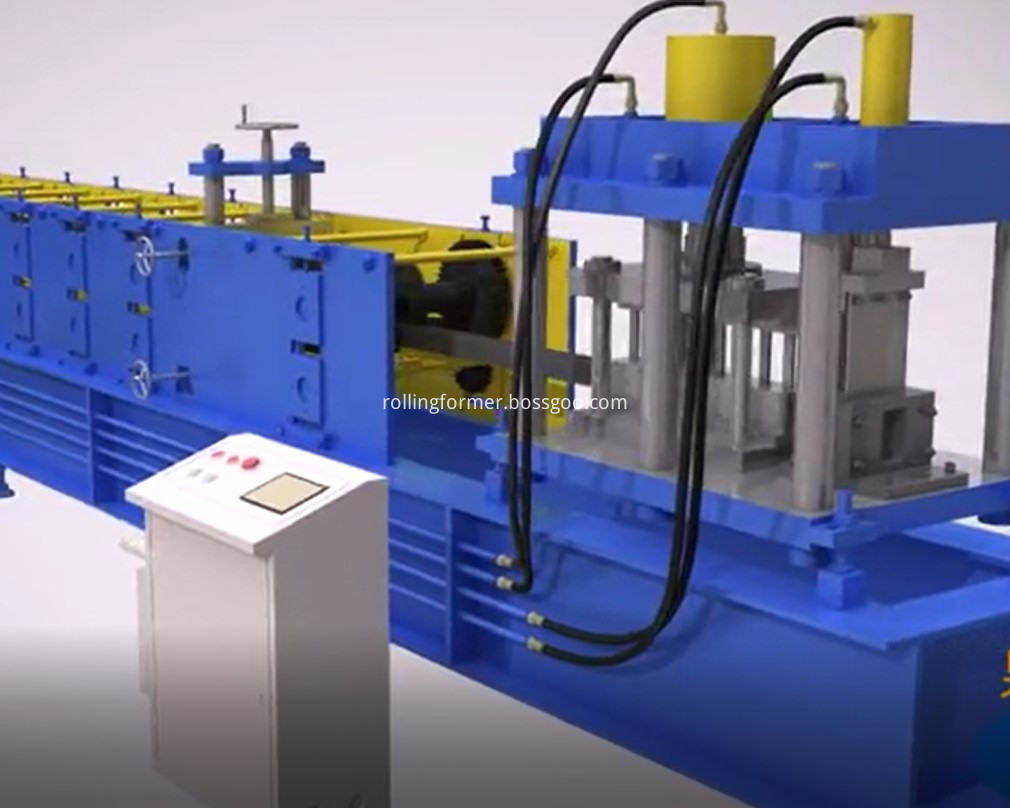

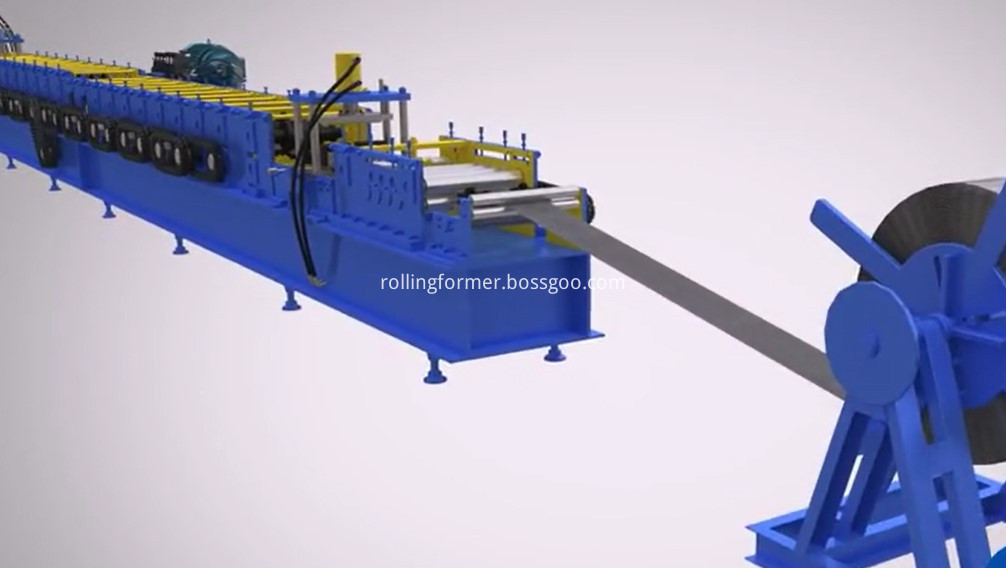

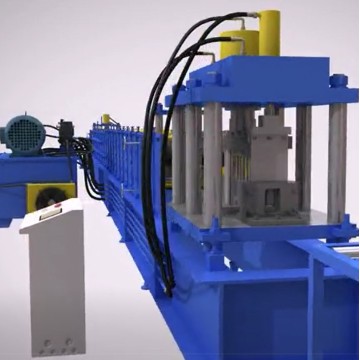

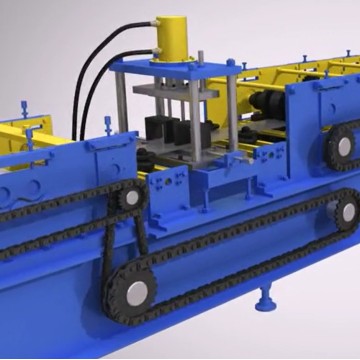

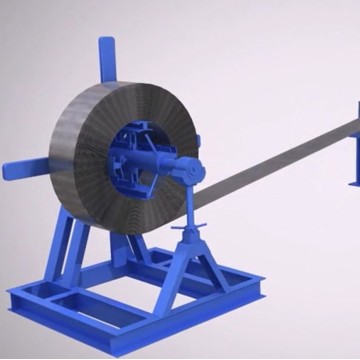

41x41 unistrut metal framing roll forming machine adopts the CNC controling system, it is a full automatic line of produce the unistrit from steel strips decoiler, flatten system, punching system, main roll forming machine, and cutting, receiving system.

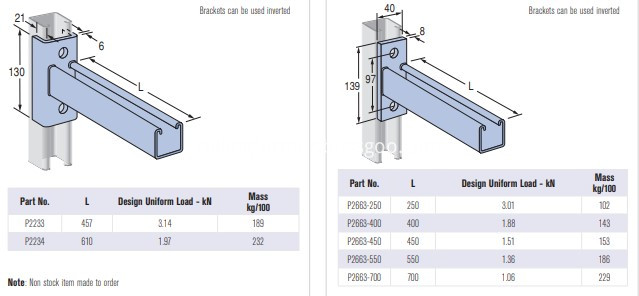

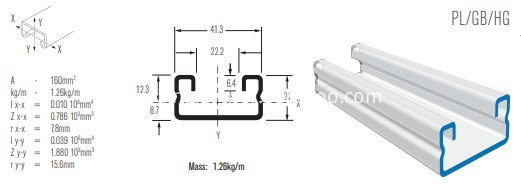

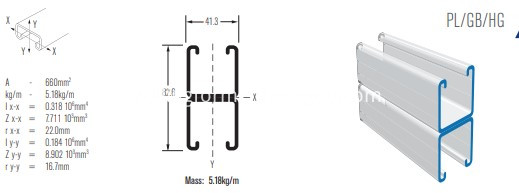

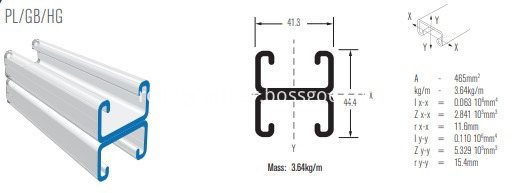

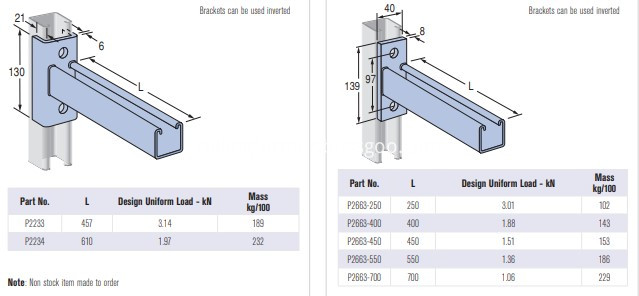

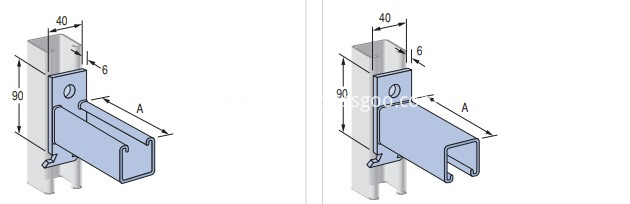

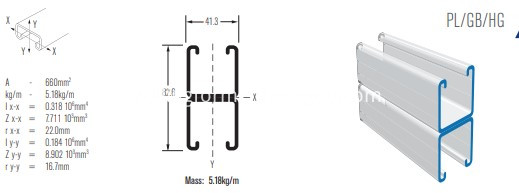

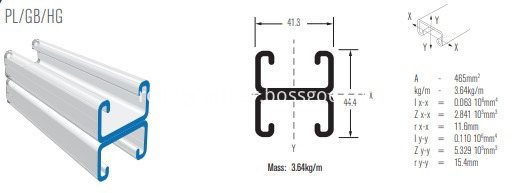

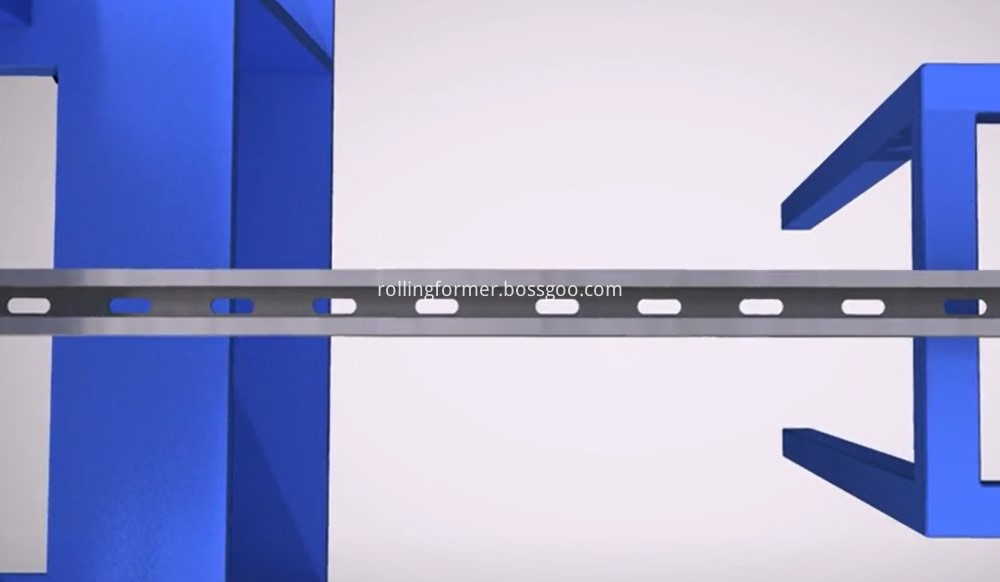

Strut channel is a standardized formed structural system used in the construction and electrical industries for light structural support, often for supporting wiring, plumbing, or mechanical components such as air conditioning or ventilation systems.

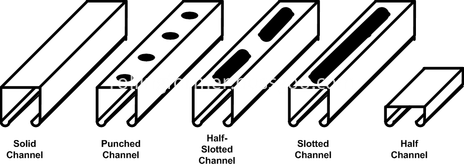

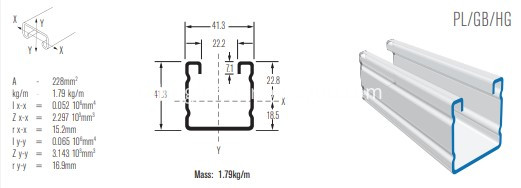

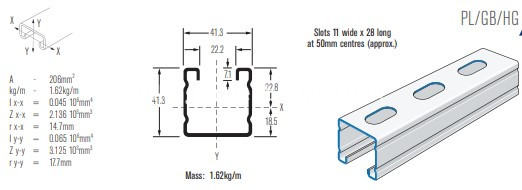

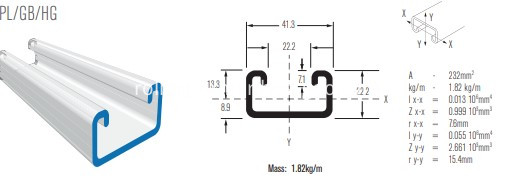

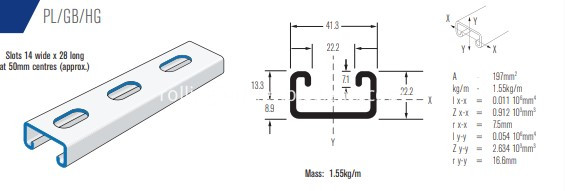

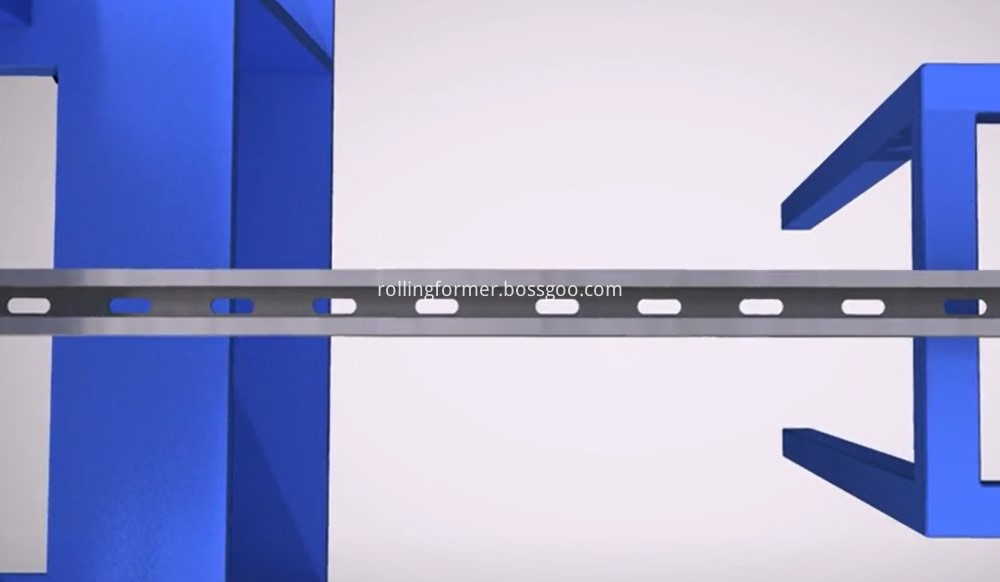

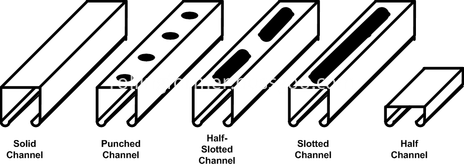

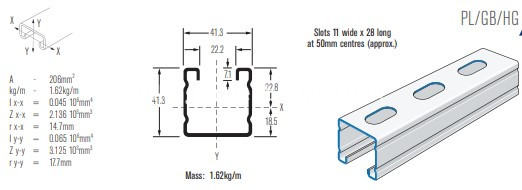

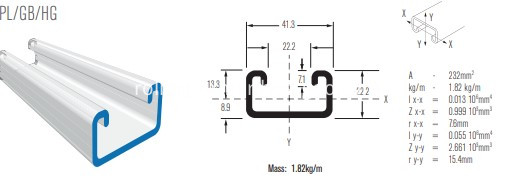

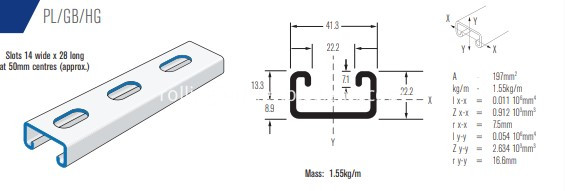

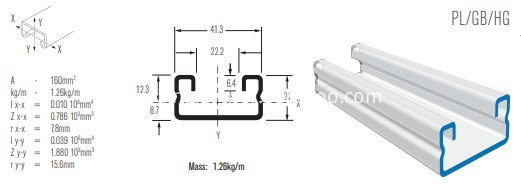

There are solid channel unistrut, punched channel unistrut, half slotted channel unistrut , slotted channel unistrut, and half channel unistrut.

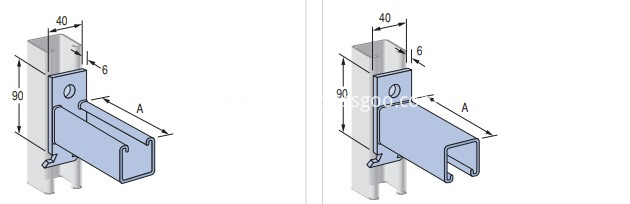

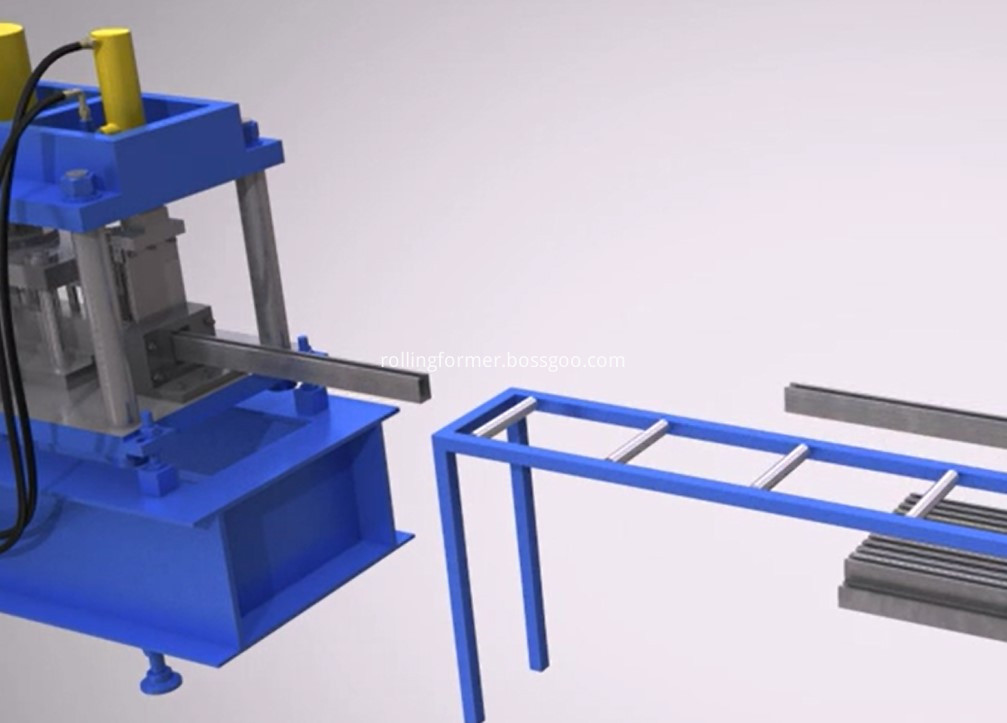

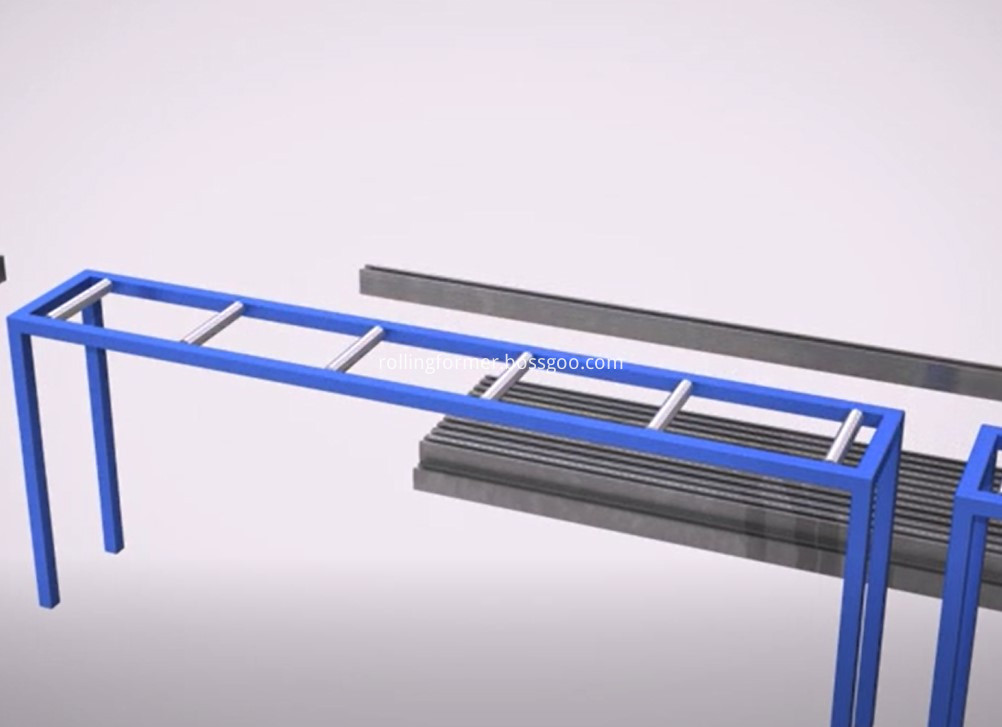

A strut is usually formed by a roll forming machine, from a metal sheet, folded over into an open channel shape with inwards-curving lips to provide additional stiffness and as a location to mount interconnecting components. The struts can be produced in mass production, by roll-formed and cutting to required certain length, such as 3 meters.

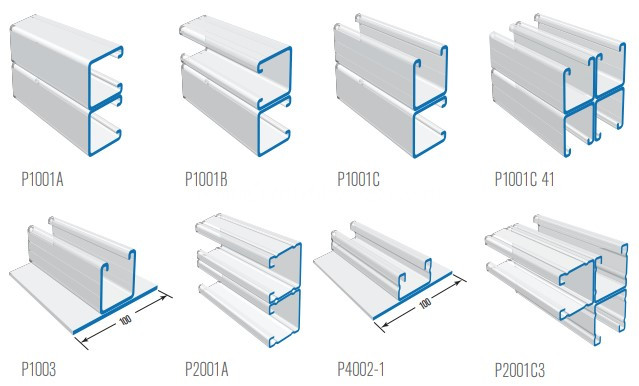

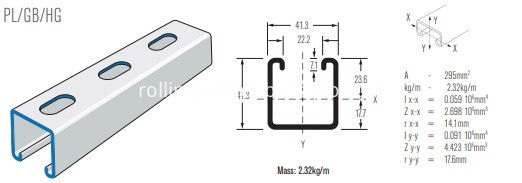

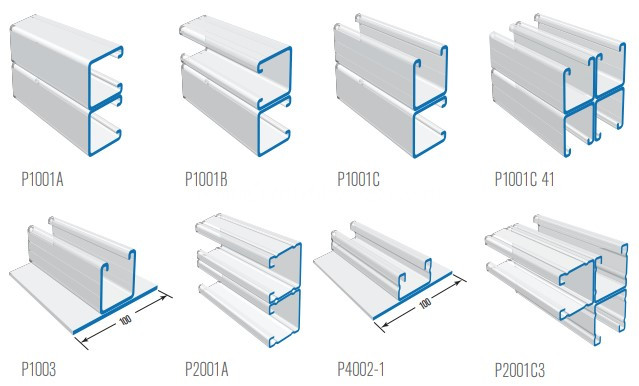

Strut channel roll forming machine is designed to produce this strut channels in different thickness, profiles, sizes.

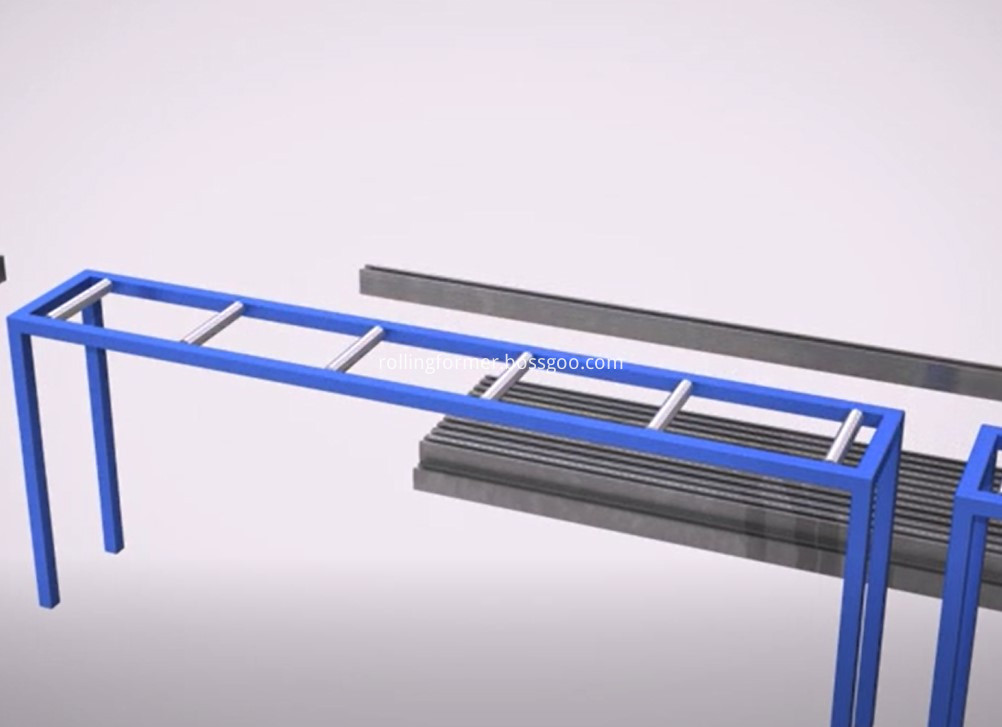

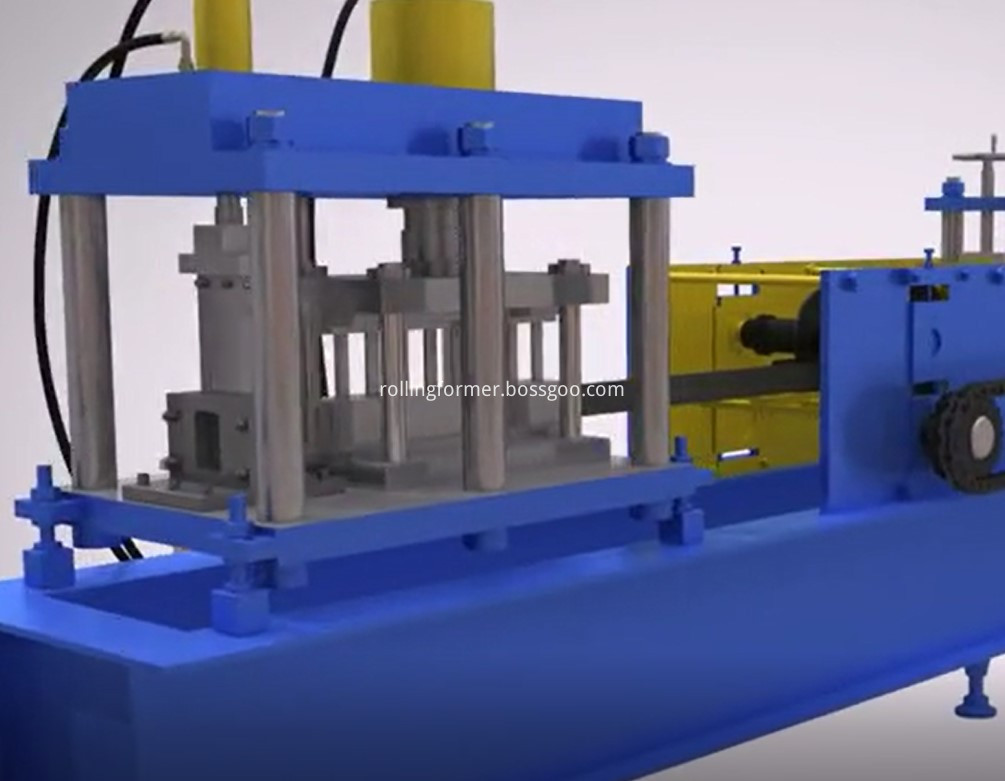

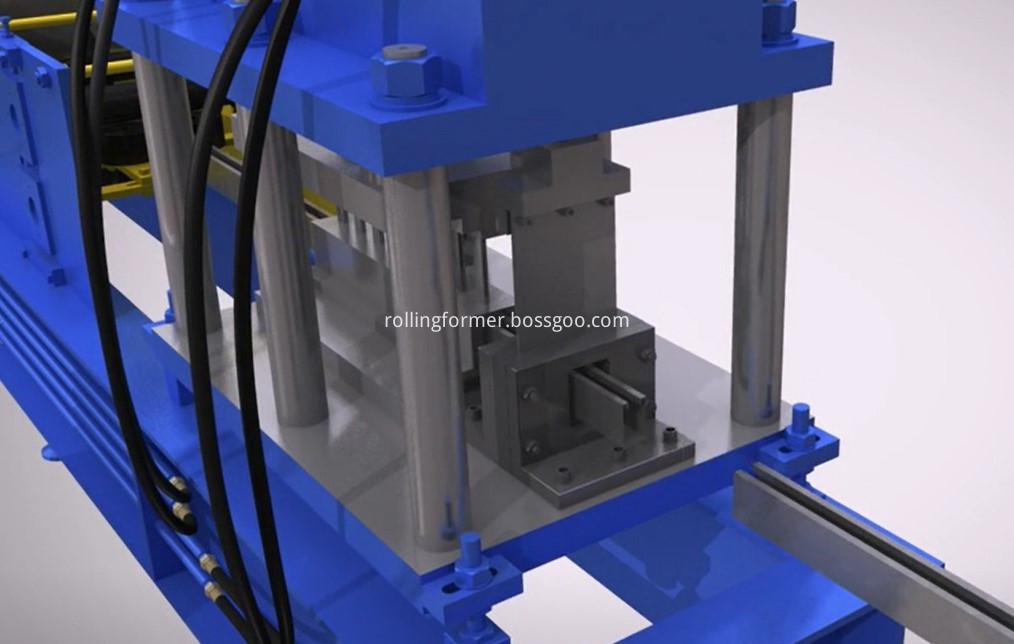

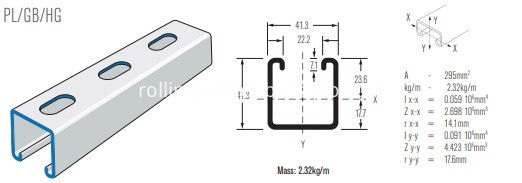

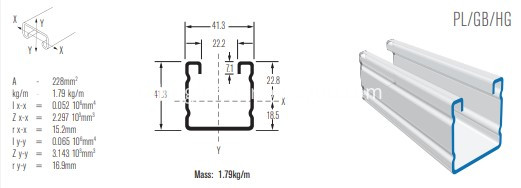

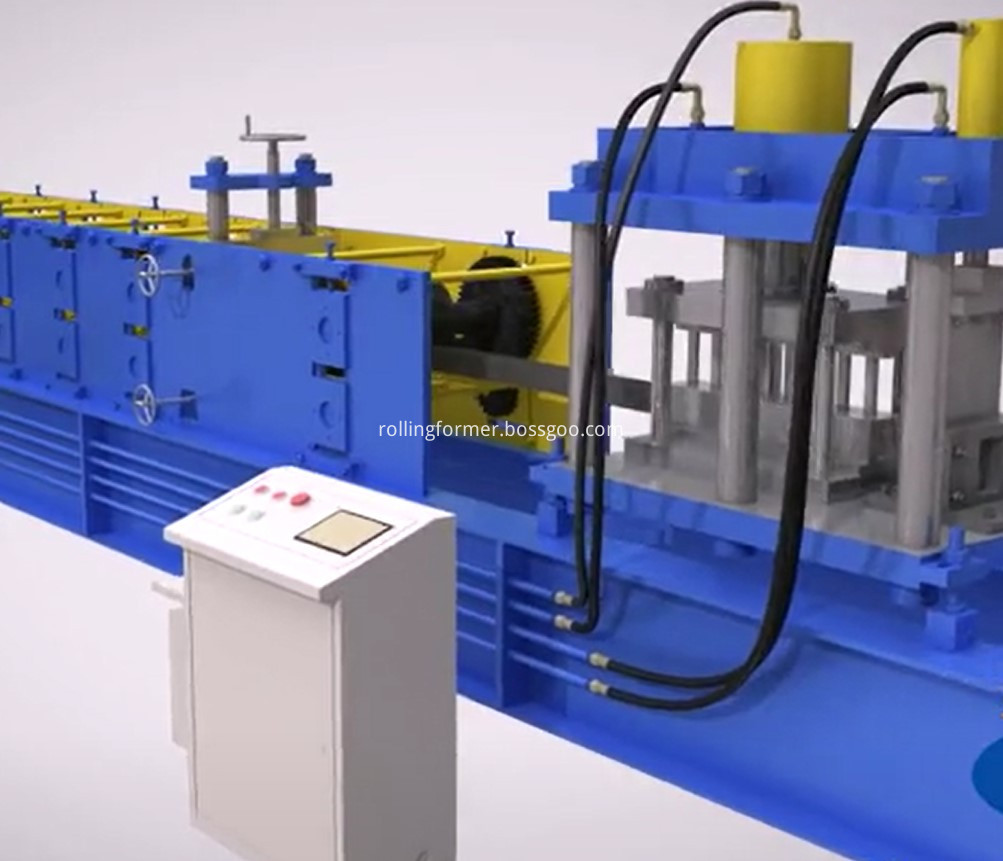

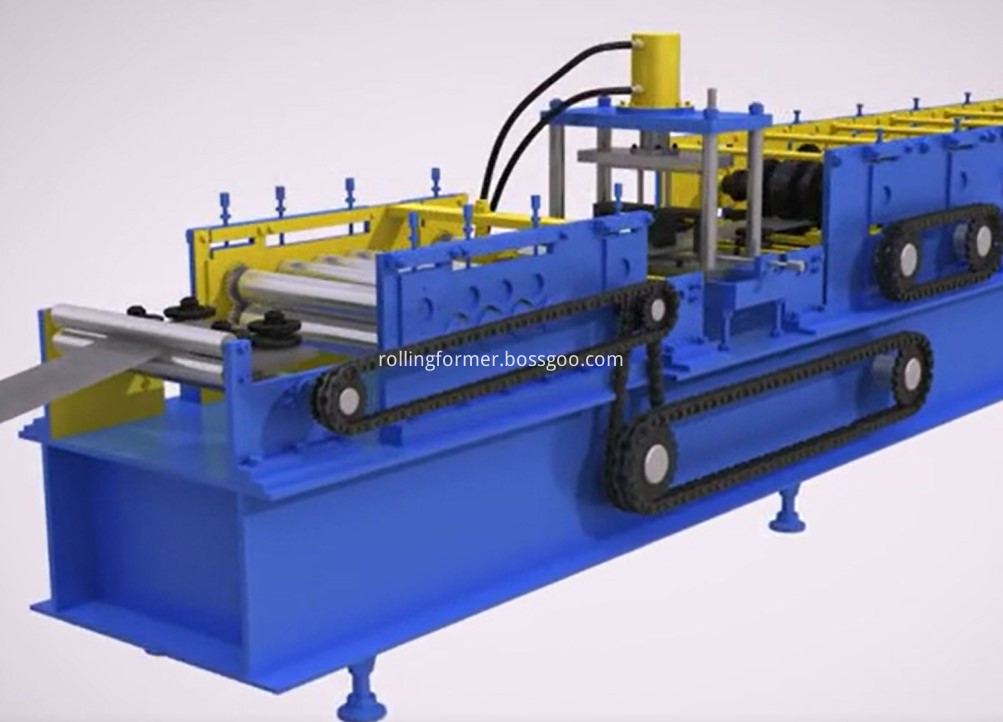

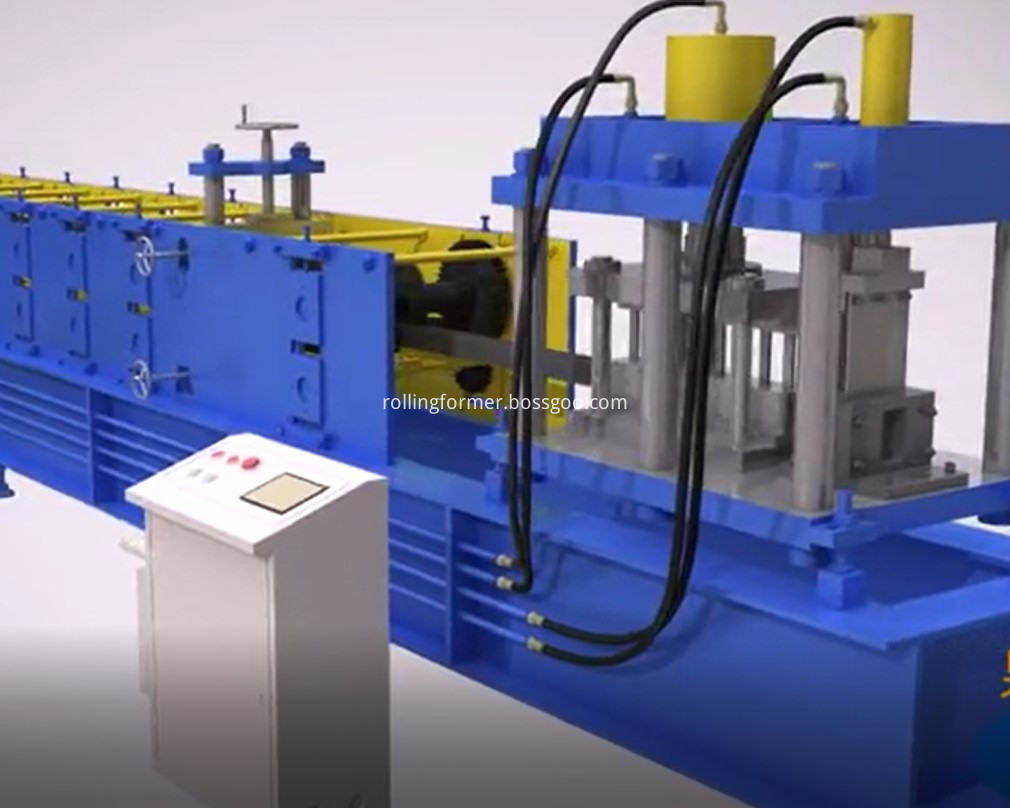

below are some pictures for your reference:

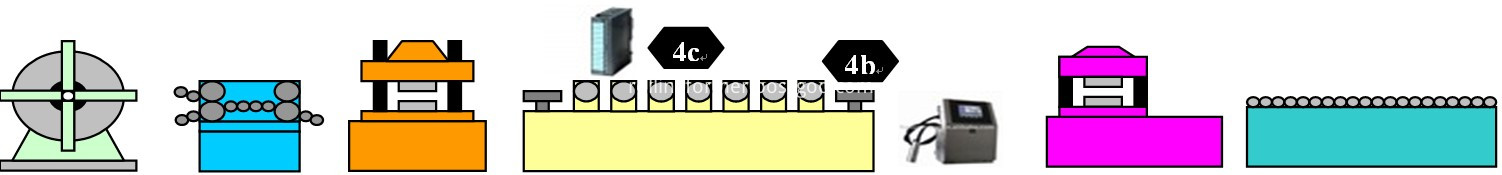

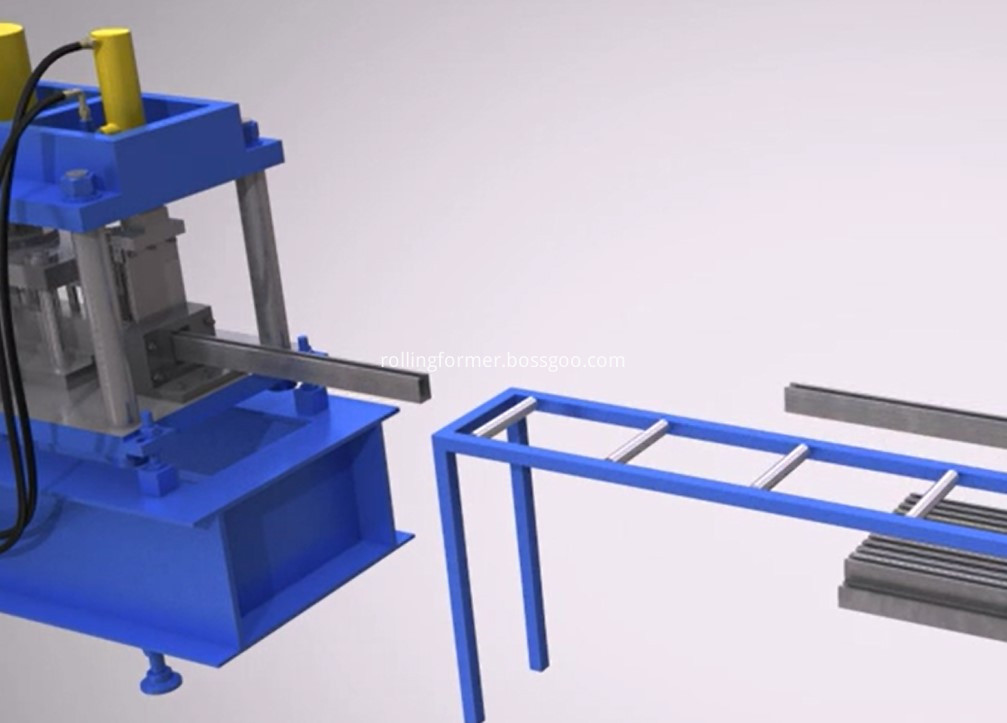

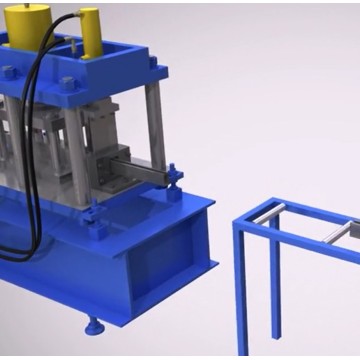

41x41 unistrut metal framing roll forming machine including below parts:

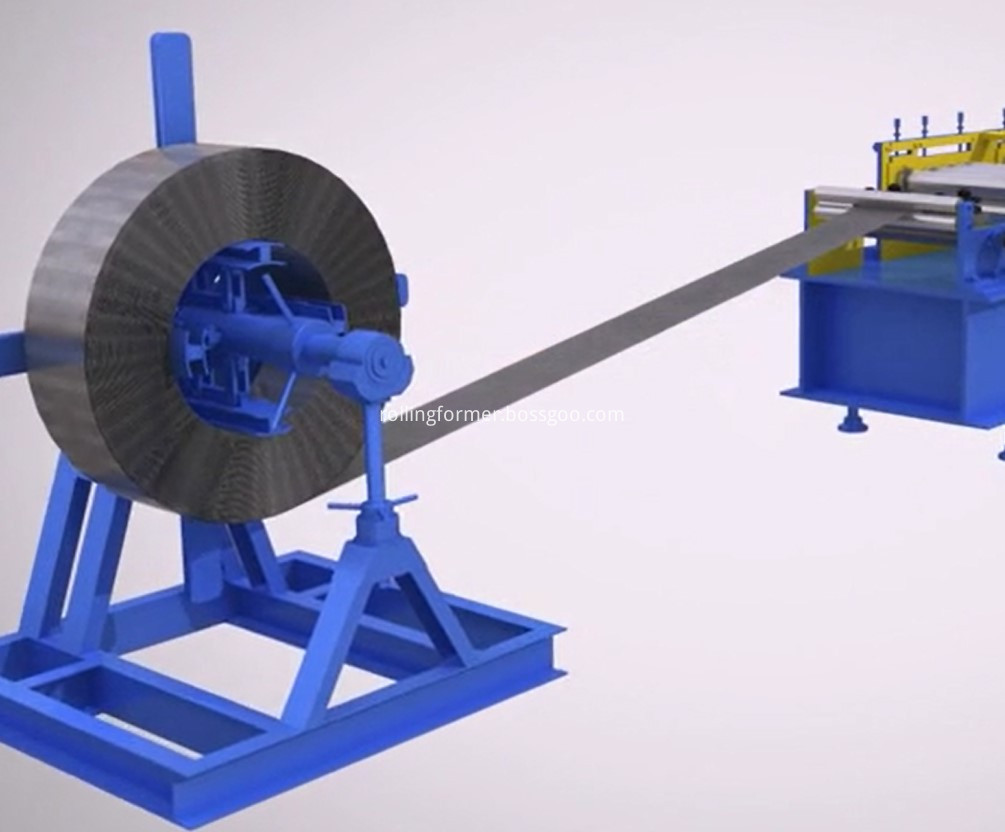

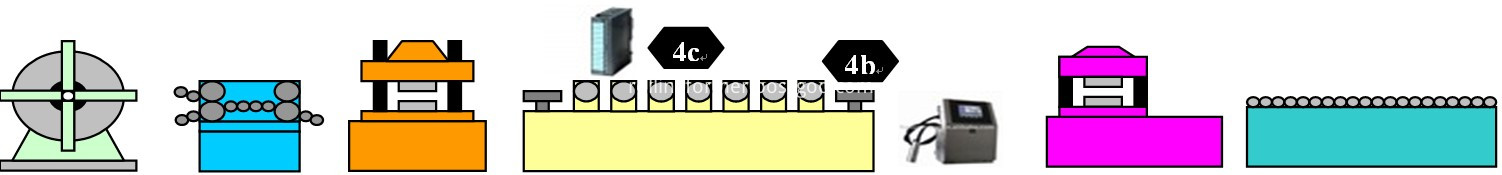

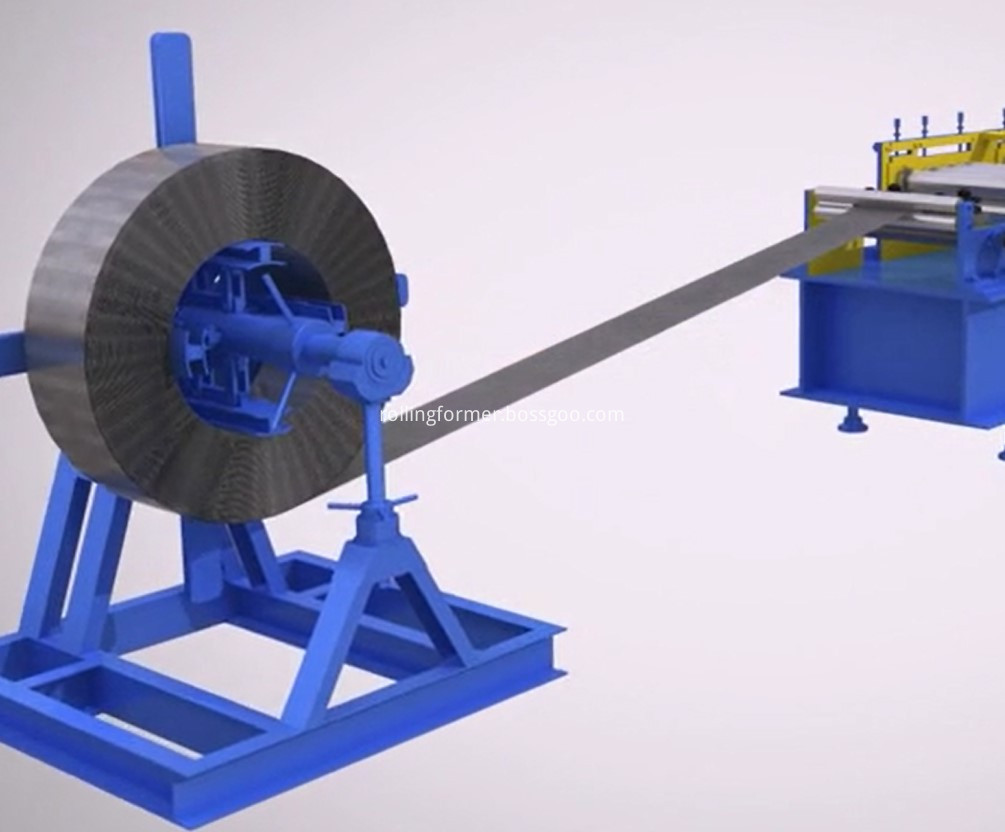

Uncoiler system, flattener feeder system, the prepun press, main roll forming machine and printer machine and the cut off , run out table.

The working process of 41x41 unistrut metal framing roll forming machine is as below:

Below is the specifications of the 41x41 unistrut metal framing roll forming machine

(Ⅰ)DECOILER SPECIFICATIONS

Coil Outside Diameter: 1400mm

Coil Inside Diameter: 508mm

Coil Weight :3 tons

Strip Width :118mm MINIMUM

Allowable Speed :20m/min

SERVO STRAIGHTENER/FEEDER

Speed:20m/min MINIMUM

Accuracy:±0.15mm

Motor:2.2kW

Strip Width:118mm MINIMUM

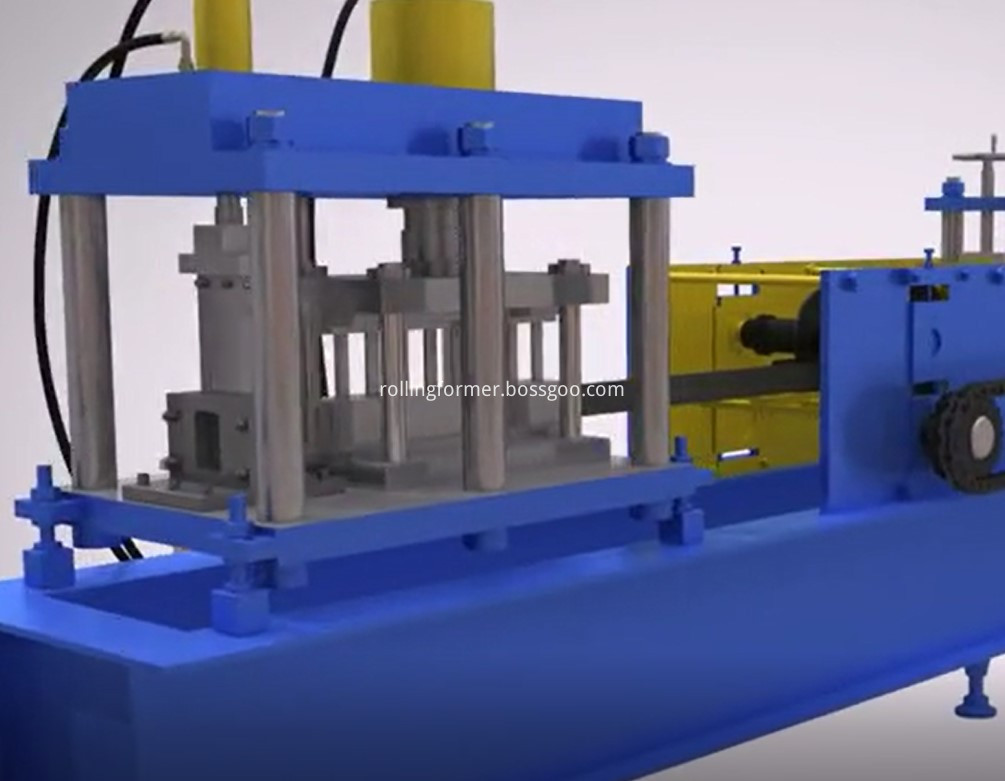

MECHANICAL PRESS

Tonnage: 40T

Bed size : hope you can send your size to us to design the machine

Stroke : 80 stroke/minute based on a feed of 250mm

Servo Feeder : 20m/minute

Accuracy:±0.15mm

Thickness of Material:2.5mm According to your required

Control system: PLC Delta

Uncoiler system:3Ton Manual Operation

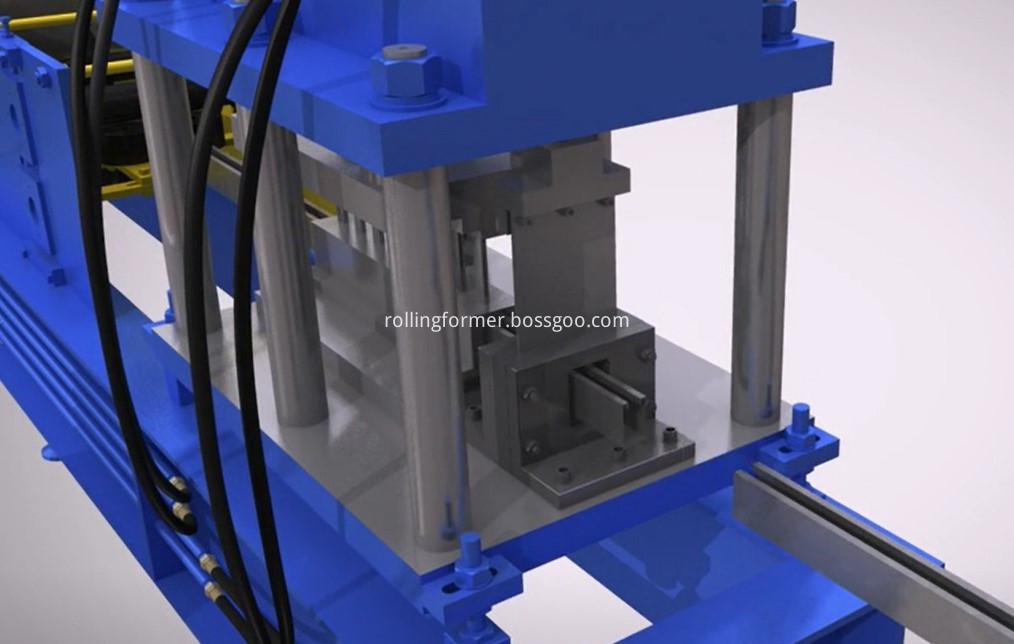

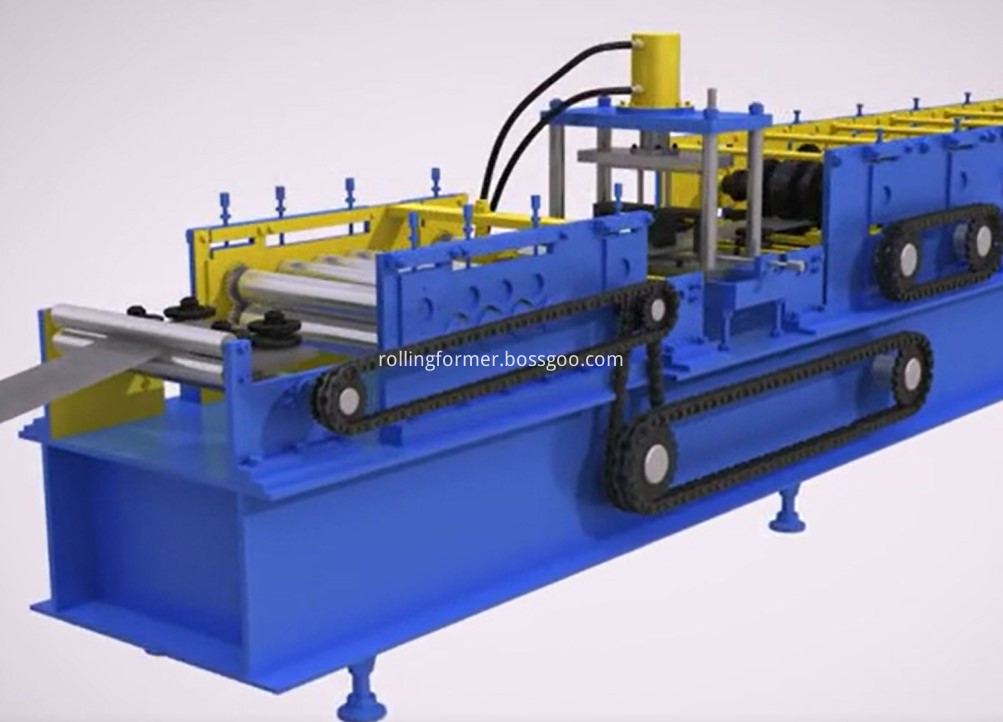

Forming by rolling:Roll 18 rows

Roller material:GCR15 Aluminium processing after quenchin HRC58-62℃,Chrome plated

Shaft and the diameter of axle 45#Aluminium-processing ,diameter of axle=¢70mm

Main part power:15kw

Hydraulic pressure:12Mpa

Scissor material : Cr12Mov, herd steel HRC 58-62℃

length tolerance

3m±1.5mm

voltage:380V, 50HZ,3 phase(adjustable by customer needs)

Frame form:arch type

Driving Method:Sprocket and Chains

Size:length*Width*Height - 8.8*1.85*1.5m Main machine

weight:15T

If you want to know more about the 41x41 unistrut metal framing roll forming machine and other rollformer lines, such as cable tray roll forming machine, CZ purline roll forming machine, steel stud and stracks rollforme equipments, you can contact me freely !

.png) Contact Now

Contact Now